MENU

FJ | FJD

FJ | FJD

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

You are about to leave this site.

Please be aware that your current cart is not saved yet and cannot be restored on the new site nor when you come back. If you want to save your cart please login in into your account.

No results found

Search Suggestions

CelliGen 510

Cell Culture Impellers

Videos not loading, because cookies have been rejected. Change your

BioCommand Setup

Videos not loading, because cookies have been rejected. Change your

Product Information

SIP benchtop reactors designed to meet the needs of R&D through production.You will find additional download material at the bottom of this page

Services (6)

6 Services

|

|

|

|

|

|

|

|

|

|

Catalog no.

0082140299

|

Show more Products

Added to Your Cart

Product Information

Applications

Features

Product Information

The CelliGen 510 is a compact sterilizable-in-place cell culture system ideal for pilot to small scale production processes. The modular design features a wide variety of standard options allowing this system to be flexible enough to meet most process requirements.

Gas flow

• Various combinations of one, two, three or four TMFCs:

0.06 – 3 SLPM

0.3 – 15 SLPM

0.6 – 32 SLPM

1 – 64 SLPM

• Air Wash System with TMFC (0 – 15 or 0 – 32 SLPM)

• Overlay with TMFC (0 – 15 or 0 – 32 SLPM)

• Overlay (valve only)

Exhaust line

• Exhaust condenser

• Manual or automatic pressure control

Impellers

• Rushton-type – Used commonly for robust cell lines such as bacteria, yeasts, and algae, where maximum OTR is desired.

• Pitched-blade – Commonly used with mammalian, insect or other shear sensitive cell lines for batch, fed-batch or continuous cultures. Produces axial and radial mixing. Provided as standard with the CelliGen 510 bioreactors.

• Marine – Commonly used with mammalian, insect, or other shear sensitive cell lines for batch, fed-batch or continuous cultures. Produces axial mixing

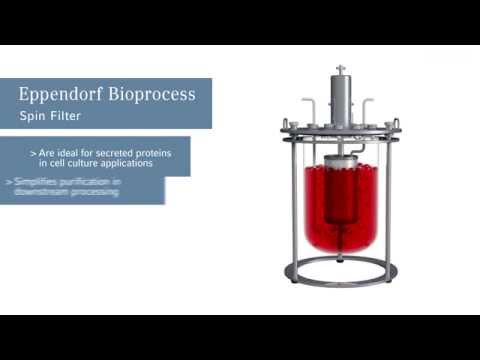

• Spinfilter – For suspension or microcarrier cultures where a dip tube inside the filter withdraws cell media as harvest or waste

• Cell-Lift – Specially designed to provide uniform circulation for both suspension and microcarrier cultures. Can be used with optional decanting columns for perfusion cultures

• Packed-bed – For secreted products from anchorage-dependent and suspension cells, this impeller immobilizes cells in a bed of Fibra-Cel® Disks to provide extremely high cell densities

Sensors

• Single or redundant pH/DO

• Redox

• Foam/level

Addition and sampling

• Resterilizable sampling valve

• Resterilizable addition valves (4 max)

• Resterilizable addition/harvest valve with dip tube (2 max)

• 1.5 in sanitary fitting 7-port septum

• Addition vessels (glass/stainless steel)

• Decanters

• Sterile sampling assembly

Documentation packages to support qualification in GMP regulated processes

• Basic Package

• Basic Plus Package

• Enhanced Package

Utility regulator & pre-filter kits

• Process air pre-filter/regulator kit

• Instrument air pre-filter/regulator kit

• Water pre-filter/regulator kit

• Process steam regulator kit

• Utility steam pre-filter/regulator kit

• Utility connection kit

Additional options

• Sprayballs for clean-in-place of vessel

• External variable-speed pumps

• External scales

• Spare parts kits

• Preventative maintenance kits

• Mobile table

• System passivation

• Glycol/chiller heat exchanger

Gas flow

• Various combinations of one, two, three or four TMFCs:

0.06 – 3 SLPM

0.3 – 15 SLPM

0.6 – 32 SLPM

1 – 64 SLPM

• Air Wash System with TMFC (0 – 15 or 0 – 32 SLPM)

• Overlay with TMFC (0 – 15 or 0 – 32 SLPM)

• Overlay (valve only)

Exhaust line

• Exhaust condenser

• Manual or automatic pressure control

Impellers

• Rushton-type – Used commonly for robust cell lines such as bacteria, yeasts, and algae, where maximum OTR is desired.

• Pitched-blade – Commonly used with mammalian, insect or other shear sensitive cell lines for batch, fed-batch or continuous cultures. Produces axial and radial mixing. Provided as standard with the CelliGen 510 bioreactors.

• Marine – Commonly used with mammalian, insect, or other shear sensitive cell lines for batch, fed-batch or continuous cultures. Produces axial mixing

• Spinfilter – For suspension or microcarrier cultures where a dip tube inside the filter withdraws cell media as harvest or waste

• Cell-Lift – Specially designed to provide uniform circulation for both suspension and microcarrier cultures. Can be used with optional decanting columns for perfusion cultures

• Packed-bed – For secreted products from anchorage-dependent and suspension cells, this impeller immobilizes cells in a bed of Fibra-Cel® Disks to provide extremely high cell densities

Sensors

• Single or redundant pH/DO

• Redox

• Foam/level

Addition and sampling

• Resterilizable sampling valve

• Resterilizable addition valves (4 max)

• Resterilizable addition/harvest valve with dip tube (2 max)

• 1.5 in sanitary fitting 7-port septum

• Addition vessels (glass/stainless steel)

• Decanters

• Sterile sampling assembly

Documentation packages to support qualification in GMP regulated processes

• Basic Package

• Basic Plus Package

• Enhanced Package

Utility regulator & pre-filter kits

• Process air pre-filter/regulator kit

• Instrument air pre-filter/regulator kit

• Water pre-filter/regulator kit

• Process steam regulator kit

• Utility steam pre-filter/regulator kit

• Utility connection kit

Additional options

• Sprayballs for clean-in-place of vessel

• External variable-speed pumps

• External scales

• Spare parts kits

• Preventative maintenance kits

• Mobile table

• System passivation

• Glycol/chiller heat exchanger

Applications

- Laboratory- and pilot-scale cell culture of mammalian, insect, and human cell lines

- Special applications such as stem cell culture, vaccine or monoclonal antibody production

- Suitable for batch, fed-batch, and continuous/perfusion processes

Features

- RPC (Reactor Process Control) software

- 32 L stainless-steel electropolished vessels with 2:1 aspect ratios

- Integrated load cell

- 3-Fixed speed peristaltic pumps for the additions, harvest, and pH control

- Benchtop or Mobile option

- Choice of pitched-blade, marine, spin filter, cell-lift or packed-bed impellers

- industrial touchscreen interface