BioFlo 320高度可配置,能够满足各种应用要求

BioFlo 320配备模拟和数字传感器通用接口和一台高度可配置的气流控制器,最多可集成6台泵机,且可组合各种玻璃和一次性生物反应罐,因此具有极高的应用灵活性。

• 适用于人细胞和动物细胞培养(包括干细胞)以及微生物发酵。

• 支持批次培养、分批补料培养、连续培养和灌流培养模式。

• 适合多种应用,包括细胞、分泌蛋白、病毒载体、质粒和小分子生产。

借助BioFlo 320,可从研发规模无缝放大至生产规模。

BioFlo 320可与各种玻璃和一次性生物反应罐组合使用,单一平台工作体积范围为400 mL - 40 L。 BioFlo 720与生物反应器控制系统组合后, BioFlo平台能够满足最广泛的一次性解决方案需求,并可将工艺规模扩大至2,000 L。

• 预装Scale Up Assist工艺放大助手软件,有助简化放大和缩小过程中重要工艺参数的计算。

• 提供适用于GMP规范工艺的验证服务包。

• Emerson® DeltaV与BioFlo 320组合能够简化技术转移、工艺放大和配方共享。

预装软件有助节省时间并降低风险。

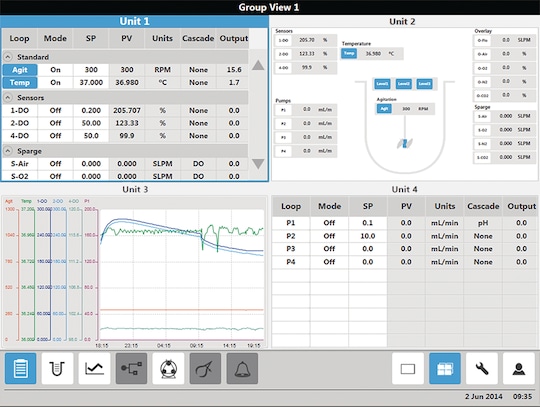

控制器和工艺监测是工艺开发成功的关键。BioFlo 320软件能够提供过程和硬件状态信息。

• 警报功能自动提示过程状态。

• 诊断界面显示硬件状态和下次维护信息。

• 自动校准——同时自动校准所有连接的DO传感器,在减少准备时间的同时确保结果一致性。