-

-

-

- Services pour bioprocédés

- Services pour centrifugeuse et rotors

- Services pour Mastercycler

- Services pour automates de pipetage

- Services pour congélateurs

- Services pour incubateurs

- Services pour agitateurs

- Services pour appareils de photométrie

- Service de contrôle de la température et de l’agitation

- Service pour pipette

-

-

-

-

- Services pour bioprocédés

- Services pour centrifugeuse et rotors

- Services pour Mastercycler

- Services pour automates de pipetage

- Services pour congélateurs

- Services pour incubateurs

- Services pour agitateurs

- Services pour appareils de photométrie

- Service de contrôle de la température et de l’agitation

- Service pour pipette

-

-

- Centrifugeuses de paillasse

- Centrifugeuses au sol

- Centrifugeuses réfrigérées

- Microcentrifugeuses

- Centrifugeuses multi-fonctions

- Centrifugeuses haute vitesse

- Ultracentrifugeuses

- Concentrateur

- High-Speed and Ultracentrifugation Consumables

- Tubes

- Plaques

- Gestion des appareils

- Gestion des échantillons et des informations

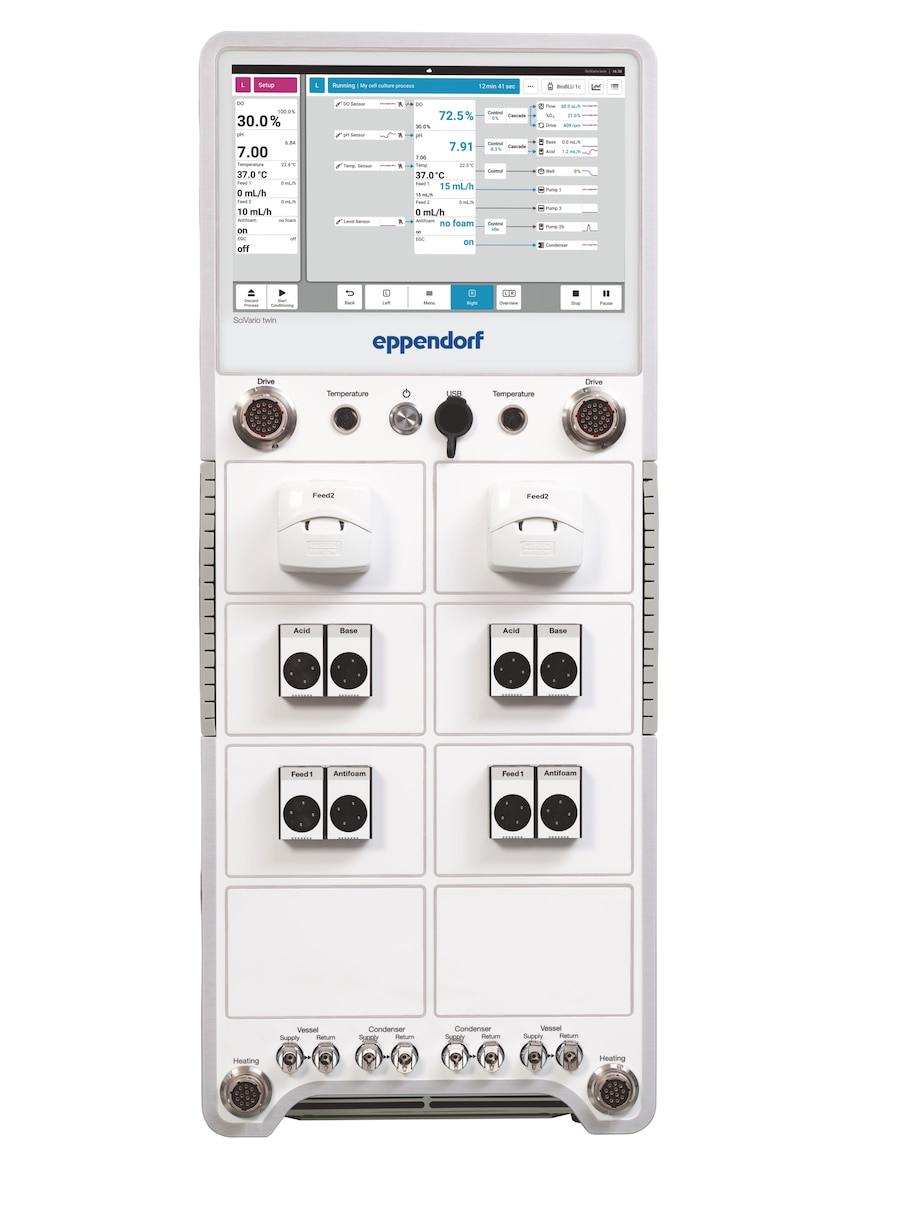

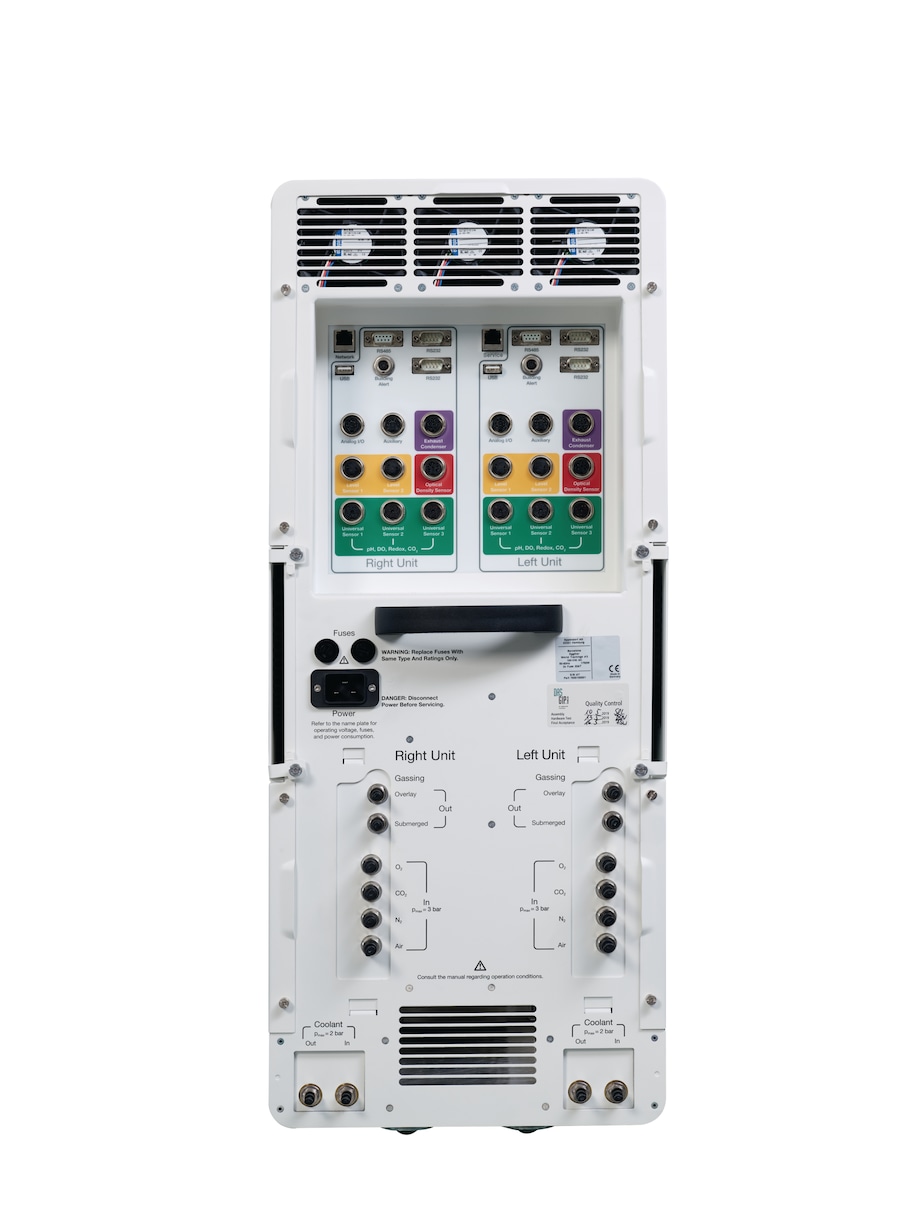

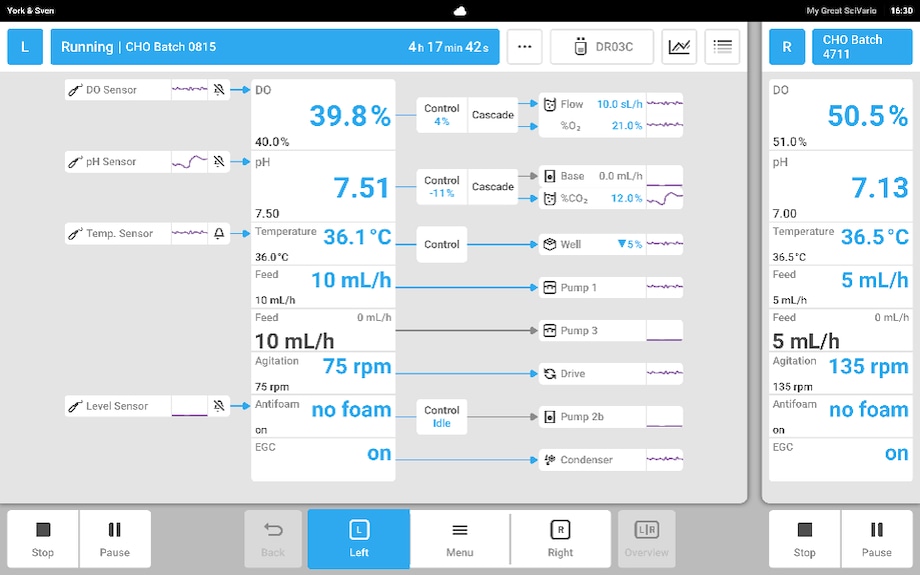

SciVario® twin

SciVario twin cropped, front, grey lines

Volume de travail de 0,2 – 3,8 L (autoclavable),

Volume de travail de 0,25 – 40 L (usage unique)

SciVario twin Angled Bench, Microbiology

Informations produit

The SciVario twin is a bench-scale parallel bioprocess controller capable of operating two bioreactors individually. It is suitable for cell culture and fermentation applications in R&D and can be used with glass and BioBLU® Single-Use Bioreactors. The SciVario twin is a modular system, making it customizable as well as easily upgradable after installation and therefore adaptable to changing requirements.

Vous trouverez plus d’informations à télécharger au bas de cette page

Produits (1)

Services (4)

Accessoires (10)

Pièces de rechange (5)

1 Produits

Réf. catalogue

7600100001

|

Afficher plus de produits

Informations produit

Données techniques

Applications

Caractéristiques

Informations produit

The SciVario twin keeps you flexible, wherever your research focus will take you in the future. The future-proof systems can adapt to changing requirements and like this reduce future capital investment.

• Run both microbial and cell culture processes without any hardware adaptations.

• Choose from a wide variety of glass and BioBLU Single-Use Bioreactors, with working volumes from 1.25 to 3.8 L for all and up to 40 L for single-use cell culture bioreactors.

• Upgrade the system’s hardware easily.

• Expand its capabilities: Integrate the SciVario twin with the DASware® software suite and BioNsight® cloud for advanced process control, and remote process monitoring and data analysis, respectively. Integrate it with the Bioprocess Autosampler for automated sampling 24/7.

Stay flexible with the future proof bay drawer concept

• Eight bays can be equipped with different pumps or other modules.

• The system can be initially delivered with custom configurations and easily upgraded with additional modules to support the changing needs in R&D.

• This concept supports you as a user to avoid additional capital investments into instruments to match future requirements.

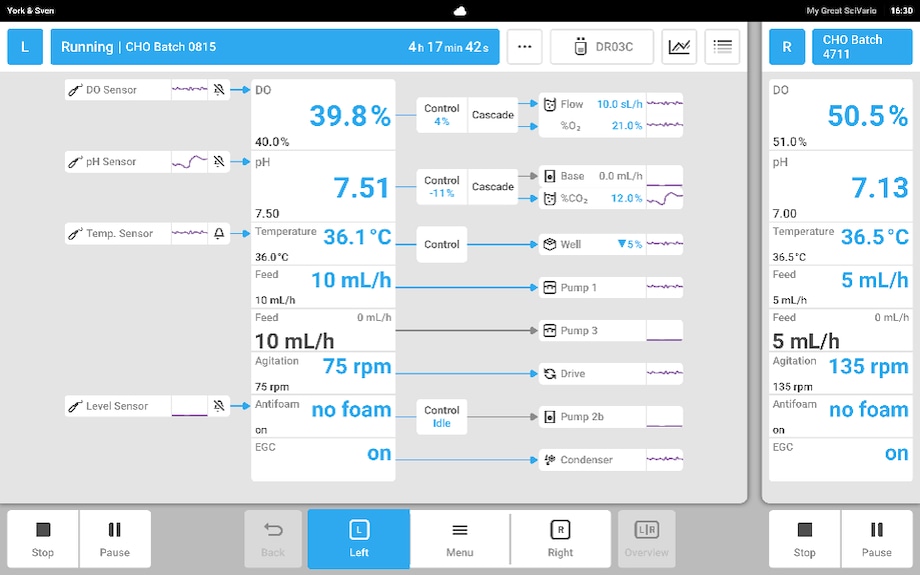

Individually control two bioreactors in parallel

• With the SciVario twin you can run one bioreactor or two bioreactors in parallel.

• The two bioreactors can be controlled individually in any combination of vessel type and working volume.

• Parallel processing allows for more runs in less time.

Optimize your workspace

• The compact design of the SciVario twin frees up bench space.

• The device can be easily moved for cleaning and servicing.

• You can easily access often used connectors/accessories, as they are placed on the front.

• Cable management guides and a storage system for accessories let you keep your bench clean and tidy.

Stay flexible in your process control

• The SciVario twin can be connected with digital and analog sensors and detects them automatically.

• The SciVario twin allows for optical pH measurement.

• Be flexible in your gassing strategy by choosing between submerged and overlay gassing with four gases with individual wide-range TMFCs.

• Flexibly add liquids with up to eight pumps per bioreactor. A wide pump flow rate enables the precise additions of small volumes as well as bigger additions to larger vessels.

• You can flexibly select the required pumps and exchange them after purchase.

• The SciVario twin is compatible with the Bioprocess Autosampler for automated sampling and bolus addition.

Software: Combine ease of use and high performance

• All critical process parameters such as temperature, gassing, pH, feeding, and others can be controlled and recorded by the base unit.

• An intuitive user interface and guided workflows assist you through your process to avoid errors.

• The integration with DASware® control offers advanced functionality, like the execution of feed profiles and scripts, process automation, and the integration of 3rd party sensors.

• The connection to BioNsight® cloud software enables remote monitoring and advanced data analysis.

Lire plus

Lire moins

Données techniques

| Caractéristiques | SciVario twin |

|---|

| Alimentation | 100 – 240 V, 50/60 Hz |

| Consommation électrique max. | 1750 W |

| Dimensions (l × P × H) | 30,6 × 34 × 75 cm / 12,0 × 13,4 × 29,5 in |

| Poids du produit | 43,1 kg |

| Bactéries/levures/champignons | oui |

| Mammifères/animaux | oui |

| Insecte | en option |

| Cuves interchangeables | oui |

| Validable | non |

| Cellules souches | oui |

|

Bioréacteurs |

|

| Récipients | Cuves en verre / à usage unique |

| Volume total | 1.3 L to 3.8 L for all variants, up to 40 L for single-use cell culture |

|

Agitation |

|

| Entraînement | Entraînements par le haut directs (cuves en verre)/magnétiques (usage unique) |

| Plages de vitesse | 60 – 1,600 rpm/25 – 1,250 rpm/25 – 1,900 rpm |

|

Injection de gaz |

|

| Alimentation en gaz | TMFC ; couverture et/ou barboteur |

| Taux d'injection de gaz par défaut | 0,1 – 1 200 sL/h |

| Mélange de gaz par défaut | Air, N2, O2 et/ou CO2 |

|

Alimentation |

|

| Tronçons de dosage par cuve | Up to 6 |

| Vitesses d'alimentation par défaut (selon le diamètre du tube) | 0,005 – 600 mL/h (petite pompe), 4,5 – 5 200 mL/h (grande pompe) |

|

Surveillance et contrôle |

|

| Condensation des gaz d'échappement | Sans liquide (Peltier) ou à base d'eau |

Applications

- Universal bench-scale controller for research and development in cell culture and microbiology

- Fermentation of bacteria, yeasts, and fungi

- Cultivation of mammalian, insect, and human cell lines

- Cultivation of stem cells

Caractéristiques

- Customizable and flexible thanks to the innovative bay-drawer concept for further extension and reconfiguration

- Integrated digital sensor technology (Mettler Toledo® ISM® and Hamilton ARC®), supporting analog sensors for pH and DO and optical DO sensors

- Optional PreSens® optical DO sensor technology for BioBLU Single-Use Bioreactors

- Variable speed pumps for accurate liquid addition and operation in batch and fed-batch mode

- Wide range TMFC to allow for individual mixing of air, N2, O2, and CO2 to headspace and/or submerged aeration

- Individual or parallel operation of two glass and/or BioBLU Single-Use Bioreactors, in any combination of bioreactor types

- Compact design, 16-40 cm of benchspace needed per vessel

- Cable management guides for a clean and tidy setup

- Temperature control block for advanced and user-friendly temperature control or temperature control via heat blankets and cooling fingers (benchtop bioreactors)

- Compatible with DASware® control software and BioNsight® cloud software

- Compatible with Bioprocess Autosampler