MENU

IE | EUR

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

IE | EUR

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

No results found

Search Suggestions

CellXpert® CS220 - CO2 Incubator Shaker

CellXpert® CS220 triple-stacked

Don´t waste an inch of lab space for lab equipment that isn´t fully designed for highest throughput per footprint – with the highest platform size vs. footprint ratio in the CO2 incubator shaker market.

CellXpert® CS220 on storage base

Convenience by design: Optional 65.7 cm/25.9 inch storage base for a single device with plenty of storage room

CellXpert® CS220 stainless steel chamber

Nowhere for contaminants to hide: Platform and sub-platform can be removed easily in under 90 seconds for full access to all chamber walls for fast cleaning – no cover sheets that hide more.

CellXpert® CS220 single device, door open

Glide-up door and slide-out platform: Saves space and ensures fast and easy experiment setup, cleaning, and service – even at the back of the chamber.

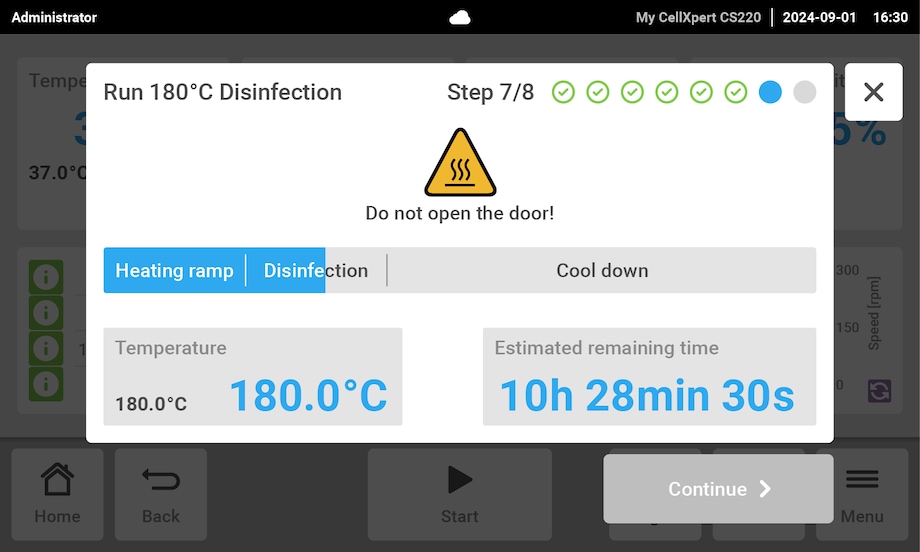

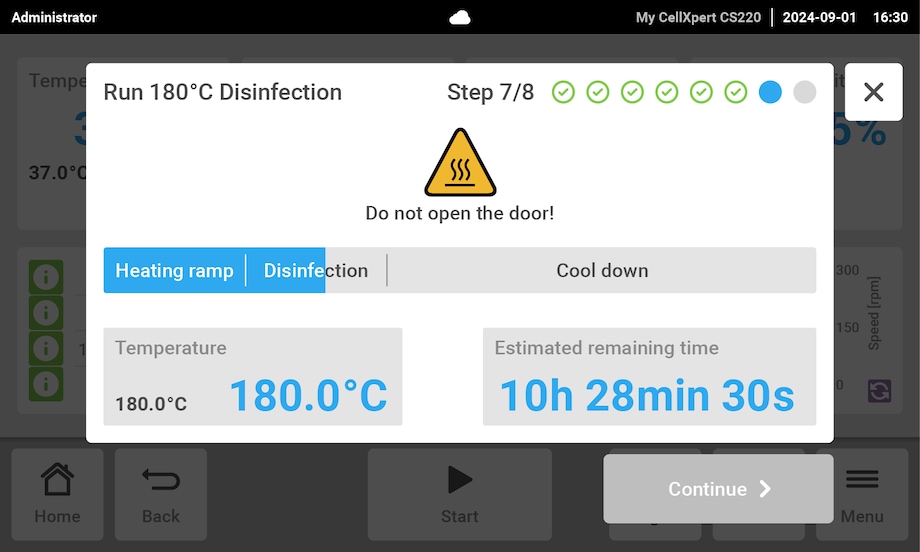

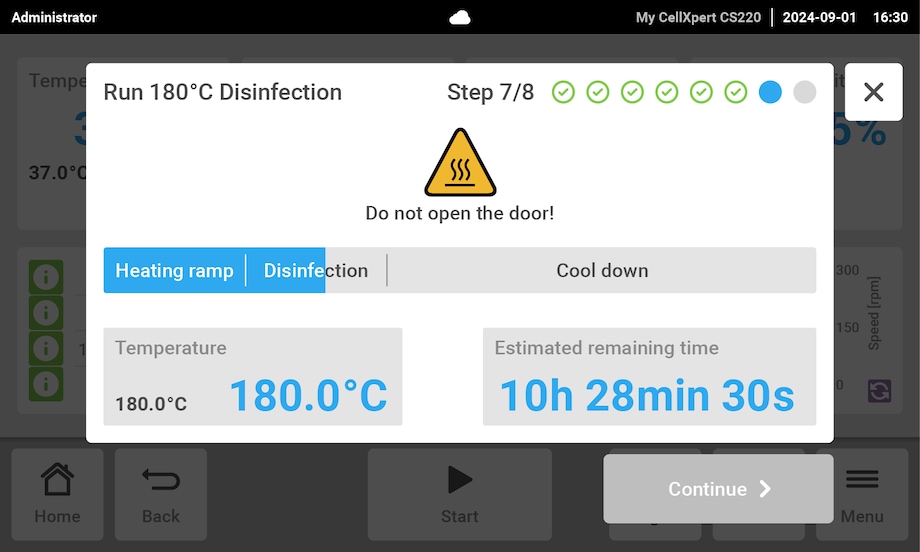

CellXpert® CS220 integrated 180 °C sterilization routine

180 °C sterilization routine integrated: incl. wizard and downloadable performance protocol; no locally restricted UV-airflow/surface-disinfection

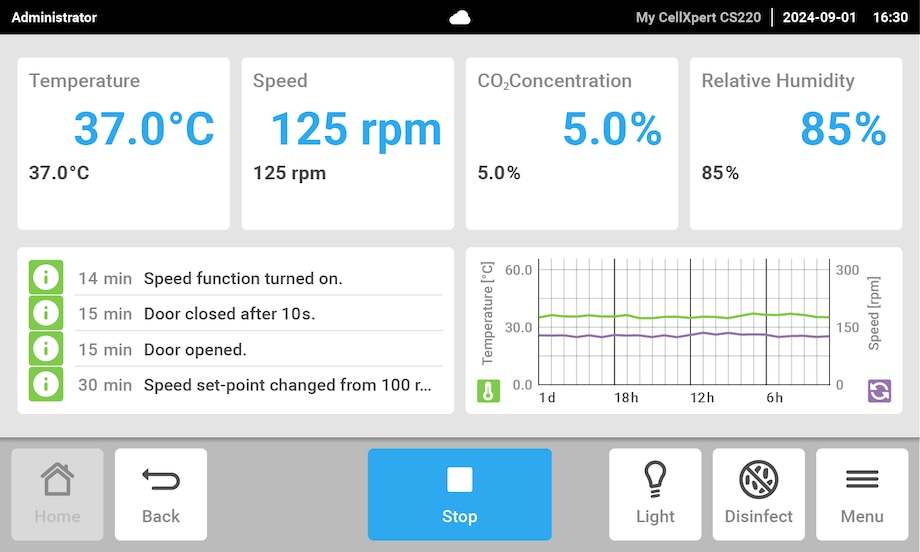

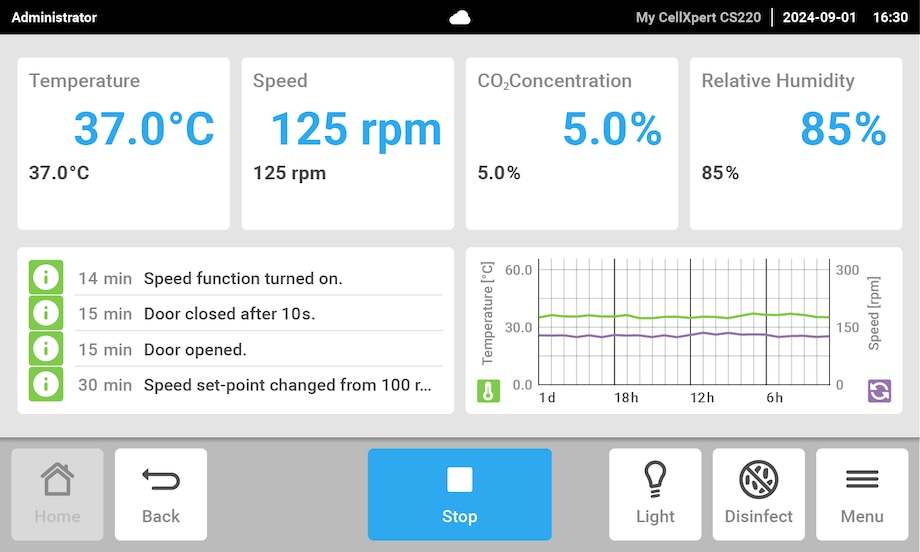

CellXpert® CS220 user interface

Full control and fast root-cause analysis: 7” touchscreen shows all setpoints and current parameters at a glance; direct visual overview of logged data/events incl. door openings and alarms, user management.

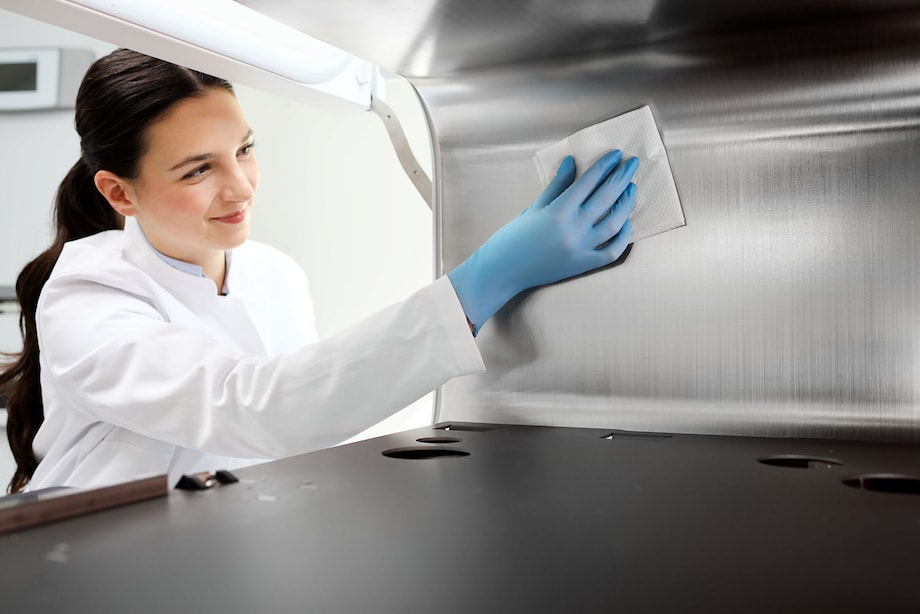

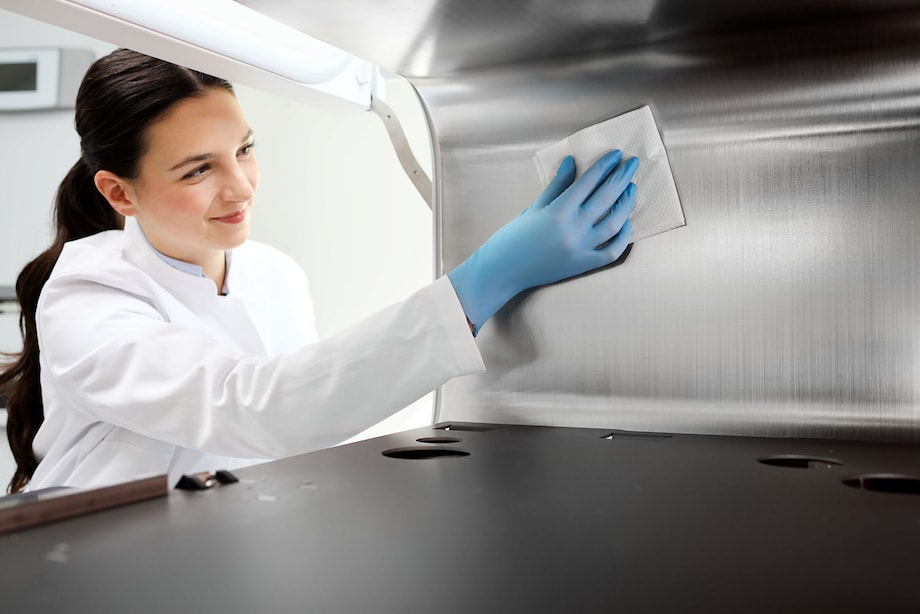

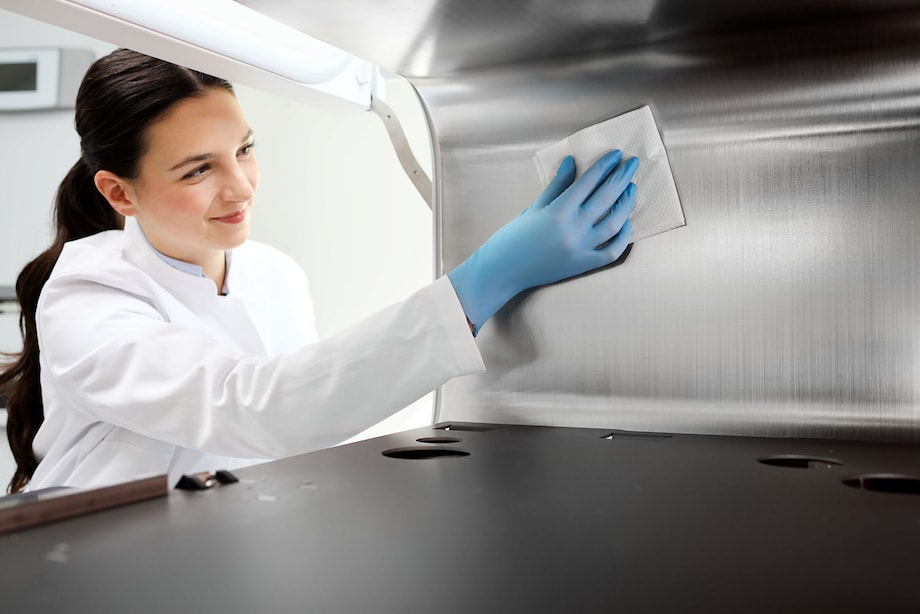

CellXpert® CS220 wipe disinfection

If it’s easy to do, it’s more likely to get done: The glide-up door and the seamless, stainless-steel chamber ensure that proper disinfection for your next batches and projects is easy and fast.

CellXpert® CS220 flask capacity

Up to 40% higher flask capacity: E.g., 8x 5L Corning®/Thomson Optimum Growth®, 25x 1L / 42x 500 mL / 102x 125 mL Corning flasks (on sticky pad)

CellXpert® CS220 accessory compatibility

Large, versatile platform: The large platform covers 4771 cm2/739 in2 and is compatible with many accessories from Eppendorf and other suppliers.

CellXpert® CS220 glide-up door and slide-out platform

Glide-up door and slide-out platform: Saves space and ensures fast and easy experiment setup, cleaning, and service – even at the back of the chamber.

CellXpert® CS220 platform handling

Easy platform handling: The lightweight anodized aluminum platform comes with comfortable handles and allows direct sticky pad placement. The platform handle directly unlocks the slide-out mechanism and decouples the platform from the sub-platform.

CellXpert® CS220 active, bidirectional rH-control

Powerful and hygienic evaporation protection: Active bidirectional, non-condensing humidity control up to 85% relative humidity

CellXpert® CS220 real-time remote monitoring, alerts and more

State-of-the art user experience: Real-time remote monitoring and e-mail/SMS alert notifications incl. escalation schemes and many more functions – with VisioNize®

CellXpert® CS220 with Eppendorf X-drive

Eppendorf X-drive: Proven and tested shaker drive with four weight-supporting shafts for 24/7 vibration-free shaking over years

Product Information

Do you want to accelerate your research while minimizing the risk of costly delays for your mammalian suspension cultures? Discover the only CO2 incubator shaker in the market with an integrated 180 °C sterilization and an outstanding capacity-to-footprint ratio. Learn more about the cost- and time-saving features that will help your team remain focused on the tasks critical to your success. IF Design Award

IF Design Award

You will find additional download material at the bottom of this page

Products (2)

Services (9)

Accessories (37)

Spare Parts (5)

VisioNize (6)

2 Products

Catalog no.

6740211020

|

Catalog no.

6740212020

|

Show more Products

Added to Your Cart

Product Information

Technical Data

Applications

Features

Product Information

Accelerate your growth – CellXpert® CS220 CO2 incubator shaker

The CellXpert CS220 is a large capacity, stackable CO2 incubator shaker that was designed to accelerate mammalian suspension culture research projects. It also minimizes the risk of costly project delays by being the first CO2 incubator shaker in the market that brings the high contamination prevention standards of CO2 incubator-based cell culture to the shaker world. Discover many cost- and time-saving features below that will help your team to focus on other success-critical tasks.

Main features

• Up to 40 % higher flask capacity: e.g., 8 x 5 L Corning®/Thomson Optimum Growth®, 25 x 1 L / 42 x 500 mL / 102 x 125 mL Erlenmeyer flasks (on sticky pad)

• 180 °C sterilization routine integrated: incl. wizard and downloadable performance protocol; no locally restricted UV-airflow/surface-disinfection

• Stainless steel chamber: Hygienic design according to EN ISO 14159:2008 standard plus only few internal parts and no drive wheel, crevices, cover sheets, cables, or heating fins inside

• Optimized throughput per lab space: Highest platform size vs. footprint ratio in the market, stackable up to 3-fold

• Save costs: Always included: slide-out platform, rH-control, touch interface, access port, sterilization routine; no UV-lamps that require frequent exchange; low gas and energy consumption

• Eppendorf X-drive: Proven and tested shaker drive with four weight-supporting shafts for 24/7 vibration-free shaking

• Glide-up door and slide-out platform: Saves space and ensures fast and easy experiment setup, cleaning and service – even at the back of the chamber

• Full control and fast root-cause analysis: 7” touchscreen shows all setpoints and current parameters at a glance; direct visual overview of logged data/events incl. door openings and alarms, user management

• Accessories & options: Storage base and feet, various service options incl. IQ/OQ-GxP-service, VisioNize® Lab Suite remote monitoring and more

• Limited time special offer: One year free subscription to VisioNize® Lab Suite Sample Safety+ including SMS notifications, response-based alert escalation, audit trail and more – check availability of VisioNize® in your country

The CellXpert CS220 is a large capacity, stackable CO2 incubator shaker that was designed to accelerate mammalian suspension culture research projects. It also minimizes the risk of costly project delays by being the first CO2 incubator shaker in the market that brings the high contamination prevention standards of CO2 incubator-based cell culture to the shaker world. Discover many cost- and time-saving features below that will help your team to focus on other success-critical tasks.

Main features

• Up to 40 % higher flask capacity: e.g., 8 x 5 L Corning®/Thomson Optimum Growth®, 25 x 1 L / 42 x 500 mL / 102 x 125 mL Erlenmeyer flasks (on sticky pad)

• 180 °C sterilization routine integrated: incl. wizard and downloadable performance protocol; no locally restricted UV-airflow/surface-disinfection

• Stainless steel chamber: Hygienic design according to EN ISO 14159:2008 standard plus only few internal parts and no drive wheel, crevices, cover sheets, cables, or heating fins inside

• Optimized throughput per lab space: Highest platform size vs. footprint ratio in the market, stackable up to 3-fold

• Save costs: Always included: slide-out platform, rH-control, touch interface, access port, sterilization routine; no UV-lamps that require frequent exchange; low gas and energy consumption

• Eppendorf X-drive: Proven and tested shaker drive with four weight-supporting shafts for 24/7 vibration-free shaking

• Glide-up door and slide-out platform: Saves space and ensures fast and easy experiment setup, cleaning and service – even at the back of the chamber

• Full control and fast root-cause analysis: 7” touchscreen shows all setpoints and current parameters at a glance; direct visual overview of logged data/events incl. door openings and alarms, user management

• Accessories & options: Storage base and feet, various service options incl. IQ/OQ-GxP-service, VisioNize® Lab Suite remote monitoring and more

• Limited time special offer: One year free subscription to VisioNize® Lab Suite Sample Safety+ including SMS notifications, response-based alert escalation, audit trail and more – check availability of VisioNize® in your country

More throughput per run: Up to 40 % higher flask capacity

Accelerate your research by increasing the culture volume per time and by ensuring same growth conditions for more flasks per run. The extra-large platform (4780 cm2/1882 in2) of the CellXpert CS220 offers more capacity than most other CO2 shakers in the market.

Capacity examples (sticky pad on universal platform):

• 8 x 5 L Corning®/Thomson Optimum Growth®

• 15 x 2 L Corning®

• 25 x 1 L Erlenmeyer

• 42 x 500 mL Erlenmeyer

• 102 x 125 mL Erlenmeyer

Accelerate your research by increasing the culture volume per time and by ensuring same growth conditions for more flasks per run. The extra-large platform (4780 cm2/1882 in2) of the CellXpert CS220 offers more capacity than most other CO2 shakers in the market.

Capacity examples (sticky pad on universal platform):

• 8 x 5 L Corning®/Thomson Optimum Growth®

• 15 x 2 L Corning®

• 25 x 1 L Erlenmeyer

• 42 x 500 mL Erlenmeyer

• 102 x 125 mL Erlenmeyer

Excellent use of lab space: Highest platform size to footprint ratio in the market

Your lab space is at a premium and you need to make the most out of it? Don't waste an inch of lab space for lab equipment that isn't fully designed for highest throughput per footprint.

Your lab space is at a premium and you need to make the most out of it? Don't waste an inch of lab space for lab equipment that isn't fully designed for highest throughput per footprint.

Effective contamination risk mitigation: Integrated 180 °C sterilization routine

Contamination is the sword of Damocles always present in a cell culture lab. Inevitably, identification of the contamination source, its removal and repetition of experiments leads to significant binding of lab staff and temporary stop of experiments. In the end, a contamination makes you lose money and valuable time-to-market, especially if it remains undetected like contamination with Mycoplasma.

Almost all current CO2 incubator shakers use UV-lights that irradiate the airstream or chamber surfaces that are in the line of sight of the UV-light. However, UV-light irradiation is per se locally restricted and does not include all critical areas where media spills and moisture can be expected e.g., underneath the platform. The CellXpert CS220 is the first shaker to apply the established and high contamination protection standards of CO2 incubator-based cell cultivation – a 180 °C sterilization. And the best part: You don't need to pay extra, it is already integrated.

Don't let contamination get in your way!

Features:

• 180 °C sterilization* instead of mere UV-decontamination of airstream or surfaces

• All chamber components and the platform are included in the sterilization routine

• Downloadable performance protocol e.g., for internal and external audits including date, time, temperature reached, and a signature field

• Wizard provides short, clear, and illustrated step-by-step instructions, to ensure a standardized and complete procedure irrespective of different users

• Access to start sterilization can be restricted by user management

* Note for stacked devices: to avoid temperature control interference during 180 °C sterilization, we recommend running the process when the device directly above is idle. The device underneath will not be affected by the sterilization process.

Contamination is the sword of Damocles always present in a cell culture lab. Inevitably, identification of the contamination source, its removal and repetition of experiments leads to significant binding of lab staff and temporary stop of experiments. In the end, a contamination makes you lose money and valuable time-to-market, especially if it remains undetected like contamination with Mycoplasma.

Almost all current CO2 incubator shakers use UV-lights that irradiate the airstream or chamber surfaces that are in the line of sight of the UV-light. However, UV-light irradiation is per se locally restricted and does not include all critical areas where media spills and moisture can be expected e.g., underneath the platform. The CellXpert CS220 is the first shaker to apply the established and high contamination protection standards of CO2 incubator-based cell cultivation – a 180 °C sterilization. And the best part: You don't need to pay extra, it is already integrated.

Don't let contamination get in your way!

Features:

• 180 °C sterilization* instead of mere UV-decontamination of airstream or surfaces

• All chamber components and the platform are included in the sterilization routine

• Downloadable performance protocol e.g., for internal and external audits including date, time, temperature reached, and a signature field

• Wizard provides short, clear, and illustrated step-by-step instructions, to ensure a standardized and complete procedure irrespective of different users

• Access to start sterilization can be restricted by user management

* Note for stacked devices: to avoid temperature control interference during 180 °C sterilization, we recommend running the process when the device directly above is idle. The device underneath will not be affected by the sterilization process.

Easy disinfection within a few minutes: Stainless steel chamber without bells and whistles

A key aspect of contamination prevention according to recommendations for Good Cell Culture Practice is frequent and complete wipe disinfection of the chamber interior – including the space behind cover sheets. For example, for CO2 incubators it is recommended to do this monthly, typically followed by a 180 °C overnight sterilization. So, the more chamber parts and crevices you have in your CO2 incubator shaker, the more time you need to invest for reliable contamination prevention. Especially if heating fins and cables covered by metal sheets are involved, this can be very time-consuming. In contrast, not cleaning and going for a "hope for the best"-approach bears a significant economic risk, especially if a contamination goes undetected over time.

The design of the CellXpert family including the CS220 follows the "If it's easy to do, it’s more likely to get done"-approach and lets you do proper cleaning within a few minutes:

• Seamless, stainless steel chamber

• Hygienic design according to EN ISO 14159:2008 standard: Fulfilled

• Only two parts (platform and sub-platform) can be removed easily within 1:30 min for full access to all chamber walls – no cover sheets that hide more

• Glide-up door glides up and out of your way so you can easily reach every corner of the device – even at the back of the chamber

• No drive wheel, crevices, cables, cover sheets, heating fins etc. inside for contaminants to hide behind

A key aspect of contamination prevention according to recommendations for Good Cell Culture Practice is frequent and complete wipe disinfection of the chamber interior – including the space behind cover sheets. For example, for CO2 incubators it is recommended to do this monthly, typically followed by a 180 °C overnight sterilization. So, the more chamber parts and crevices you have in your CO2 incubator shaker, the more time you need to invest for reliable contamination prevention. Especially if heating fins and cables covered by metal sheets are involved, this can be very time-consuming. In contrast, not cleaning and going for a "hope for the best"-approach bears a significant economic risk, especially if a contamination goes undetected over time.

The design of the CellXpert family including the CS220 follows the "If it's easy to do, it’s more likely to get done"-approach and lets you do proper cleaning within a few minutes:

• Seamless, stainless steel chamber

• Hygienic design according to EN ISO 14159:2008 standard: Fulfilled

• Only two parts (platform and sub-platform) can be removed easily within 1:30 min for full access to all chamber walls – no cover sheets that hide more

• Glide-up door glides up and out of your way so you can easily reach every corner of the device – even at the back of the chamber

• No drive wheel, crevices, cables, cover sheets, heating fins etc. inside for contaminants to hide behind

Save money and reach sustainability goals

• High flask capacity ensures lower maintenance per throughput than most other CO2 incubator shakers in the market

• Highest platform size vs. footprint ratio in the market saves valuable lab space

• Only optional with most other devices in the market, but always included in the CellXpert CS220 product package: Slide-out platform, rH-control, touch interface, access port, sterilization routine

• No UV-lamps or open water bath plastic inlays that require frequent exchange

• Low gas and energy consumption

• High flask capacity ensures lower maintenance per throughput than most other CO2 incubator shakers in the market

• Highest platform size vs. footprint ratio in the market saves valuable lab space

• Only optional with most other devices in the market, but always included in the CellXpert CS220 product package: Slide-out platform, rH-control, touch interface, access port, sterilization routine

• No UV-lamps or open water bath plastic inlays that require frequent exchange

• Low gas and energy consumption

Glide-up door and slide-out platform: Saves space and ensures fast and easy experiment setup, cleaning and service - even at the back of the chamber

The space-saving door glides up and out of your way to ensure easy vessel loading onto the slide-out platform. The platform is locked and unlocked simply by the platform handle. In addition, the slide-out subplatform can be removed easily for full access and cleaning of the chamber bottom.

The space-saving door glides up and out of your way to ensure easy vessel loading onto the slide-out platform. The platform is locked and unlocked simply by the platform handle. In addition, the slide-out subplatform can be removed easily for full access and cleaning of the chamber bottom.

For optimized device uptime: Proven and tested Eppendorf X-drive

Unexpected downtime and late results are not an option for you? And do you have more important things to do than organize repair of your CO2 incubator shaker over the weekend? The Eppendorf X-drive with four weight-supporting shafts and imbalance detection has been proven and tested in the market since years. It was designed to perform 24/7 at high loads with the Eppendorf reliability you are used to, so you can reach your goals in time and with peace of mind. Drive and drive wheel are positioned in a service drawer that opens to the front for easy access. This makes cleaning even easier and avoids the need to move the stack to have your drive checked.

Unexpected downtime and late results are not an option for you? And do you have more important things to do than organize repair of your CO2 incubator shaker over the weekend? The Eppendorf X-drive with four weight-supporting shafts and imbalance detection has been proven and tested in the market since years. It was designed to perform 24/7 at high loads with the Eppendorf reliability you are used to, so you can reach your goals in time and with peace of mind. Drive and drive wheel are positioned in a service drawer that opens to the front for easy access. This makes cleaning even easier and avoids the need to move the stack to have your drive checked.

Smart cell cultivation and easy documentation – with VisioNize®

• Optimize your daily work and increase your research safety using smart devices and connectivity options:

• 7” VisioNize touch interface shows all setpoints and current parameters at a glance

• Step-by-step on-screen wizard for 180 °C sterilization

• Filter and export performance charts, events, or performance protocols for 180 °C sterilization within seconds via VisioNize® Lab Suite or the front USB-port

• Pre-installed and customer-programmed reminders e.g., for performance of a sterilization cycle, wipe disinfection, or performance checks with external sensors

• Integrated alarm system to define critical values e.g., door-opening time or gas concentration that trigger a highly visible on screen and audible alarm

• Download operation records to document cultivation conditions of individual experiments

• Set permissions and restrictions with on-board VisioNize user management

• Remote device monitoring and alert notifications with VisioNize Lab Suite

• Optimize your daily work and increase your research safety using smart devices and connectivity options:

• 7” VisioNize touch interface shows all setpoints and current parameters at a glance

• Step-by-step on-screen wizard for 180 °C sterilization

• Filter and export performance charts, events, or performance protocols for 180 °C sterilization within seconds via VisioNize® Lab Suite or the front USB-port

• Pre-installed and customer-programmed reminders e.g., for performance of a sterilization cycle, wipe disinfection, or performance checks with external sensors

• Integrated alarm system to define critical values e.g., door-opening time or gas concentration that trigger a highly visible on screen and audible alarm

• Download operation records to document cultivation conditions of individual experiments

• Set permissions and restrictions with on-board VisioNize user management

• Remote device monitoring and alert notifications with VisioNize Lab Suite

Care for your shaker – Service options

Biological shakers are fundamental to cell culture applications and must be able to run continuously for several years. Relatively small, short-term deviations in the shaker operation can have a significant impact on cultivation results, which can negatively affect the yield and/or cell expression. Eppendorf's Shaker Performance Plans ensure consistent, reliable shaker performance in accordance with manufacturer specifications. Shaker Performance Plans include a selection of preventive maintenance protocols to test and validate stable incubator performance.

Our installation qualification (IQ) and operational qualification (OQ) certification services support the requirements of your quality management and give you reliable confirmation that your biological shaker is working correctly and in accordance with the manufacturer's specifications.

Biological shakers are fundamental to cell culture applications and must be able to run continuously for several years. Relatively small, short-term deviations in the shaker operation can have a significant impact on cultivation results, which can negatively affect the yield and/or cell expression. Eppendorf's Shaker Performance Plans ensure consistent, reliable shaker performance in accordance with manufacturer specifications. Shaker Performance Plans include a selection of preventive maintenance protocols to test and validate stable incubator performance.

Our installation qualification (IQ) and operational qualification (OQ) certification services support the requirements of your quality management and give you reliable confirmation that your biological shaker is working correctly and in accordance with the manufacturer's specifications.

Be confident about your cell culture conditions: Lab monitoring, asset management & instrument alert notification with VisioNize® Lab Suite

With VisioNize Lab Suite, Eppendorf offers you a cloud-based platform that easily connects, manages, and monitors your lab devices from anywhere. Track all related device parameters such as temperature, CO2, rH, rpm as well as remaining program runtime. It also sends alert notifications via e-mail or SMS in case of anomalies.

With only one system you can manage recurring tasks such as performance of sterilization cycles, cleaning routines, or maintenance for your entire fleet centrally in one system. VisioNize Lab Suite has all the services to help you build a smart laboratory with increased sample safety, lab productivity and reliability.

Gain free, hands-on experience by connecting 3 devices for free.

Learn more about the VisioNize Lab Suite and its services

With VisioNize Lab Suite, Eppendorf offers you a cloud-based platform that easily connects, manages, and monitors your lab devices from anywhere. Track all related device parameters such as temperature, CO2, rH, rpm as well as remaining program runtime. It also sends alert notifications via e-mail or SMS in case of anomalies.

With only one system you can manage recurring tasks such as performance of sterilization cycles, cleaning routines, or maintenance for your entire fleet centrally in one system. VisioNize Lab Suite has all the services to help you build a smart laboratory with increased sample safety, lab productivity and reliability.

Gain free, hands-on experience by connecting 3 devices for free.

Learn more about the VisioNize Lab Suite and its services

Eppendorf Bioprocess and harvesting solutions

Are you ready for scale-up or looking for a solution to harvest your cultivation products?

When the time comes to scale-up, you can expand your process with Eppendorf Bioprocess solutions – we are here to bring the tools and expertise required. We offer small scale to pilot/production scale bioprocess systems, ranging from 60 mL small-scale to 2,400 L fitting your specific application. Application and service support is there to assist you and your work – from first inquiry through final production. To harvest your large batches, Eppendorf provides matching sample separation solutions. Especially our high-speed centrifuges can help you to save handling time and efficiently handle volumes of 4 x 1.5 L or more.

Are you ready for scale-up or looking for a solution to harvest your cultivation products?

When the time comes to scale-up, you can expand your process with Eppendorf Bioprocess solutions – we are here to bring the tools and expertise required. We offer small scale to pilot/production scale bioprocess systems, ranging from 60 mL small-scale to 2,400 L fitting your specific application. Application and service support is there to assist you and your work – from first inquiry through final production. To harvest your large batches, Eppendorf provides matching sample separation solutions. Especially our high-speed centrifuges can help you to save handling time and efficiently handle volumes of 4 x 1.5 L or more.

Read More

Read Less

Technical Data

| Specifications | CellXpert® CS220 – 2.5 cm/1 in orbit | CellXpert® CS220 – 5.1 cm/2 in orbit |

|---|

| Capacity | 224 L (7.9 ft³) | 224 L (7.9 ft³) |

| Power supply | 220 – 240 V ±10 %, 50 – 60 Hz | 220 – 240 V ±10 %, 50 – 60 Hz |

| Dimensions (W × D × H) | 131.8 × 80.5 × 66.1 cm / 51.9 × 31.7 × 26.0 in | 131.8 × 80.5 × 66.1 cm / 51.9 × 31.7 × 26.0 in |

| Product weight | 240 kg / 529 lb | 240 kg / 529 lb |

| High temperature disinfection (HTD) | 180 °C | 180 °C |

| Sealed inner glass doors | no | no |

| Segmented door options | – | – |

| Temperature control increment | 0.1 °C | 0.1 °C |

| Temperature stability at 37 °C | (at 22 °C ambient) ±0.1 °C | (at 22 °C ambient) ±0.1 °C |

| Temperature range | Ambient +8 °C to 60 °C | Ambient +8 °C to 60 °C |

| Audible and visual alarms | yes | yes |

| Temperature uniformity | ±0.3 °C at 37 °C | ±0.3 °C at 37 °C |

| CO2 range | 0.1 % – 20 % | 0.1 % – 20 % |

| CO2 control increment | 0.1 % | 0.1 % |

| CO2 stability at 5 % CO2 | ±0.1 % | ±0.1 % |

| Drive mechanism | Eppendorf X-Drive | Eppendorf X-Drive |

| CO2 uniformity | ±0.1 % | ±0.1 % |

| Number of shelves (standard/max) | – | – |

| Data export interface | USB, Ethernet, VisioNize® | USB, Ethernet, VisioNize® |

| Benchtop (B), Under Bench (U), Floor (F) or Stackable (S) | F, S (x3) | F, S (x3) |

| Access port | 1 | 1 |

| On-board data logging | yes | yes |

| BMS relay | yes | yes |

| Platform size (cm/in) | 51.4 × 93 cm (20.2 × 36.6 in) | 51.4 × 93 cm (20.2 × 36.6 in) |

| Refrigerated | no | no |

| Slide-out platform | yes | yes |

| Door opening | glide up | glide up |

| Speed range | 20 – 300 rpm with 2.54 cm (1 in) orbit, 20 – 250 rpm with 5.1 cm (2 in) orbit | 20 – 300 rpm with 2.54 cm (1 in) orbit, 20 – 250 rpm with 5.1 cm (2 in) orbit |

| Capacity | extra large | extra large |

| CO2 accuracy | ±0.3% at 5% CO2 | ±0.3 % at 5 % CO2 |

| CO2 sensor type | NDIR | NDIR |

| Relative humidity range | Up to 85 % | Up to 85 % |

| Relative humidity sensor type | bidirectional control | bidirectional control |

| Relative humidity accuracy | ±5 % | ±5 % |

| Relative humidity sensor type | Capacitive sensor | Capacitive sensor |

| Relative humidity control increment | 1 % | 1 % |

| Relative humidity stability | ±2 % | ±2 % |

| Remote Device Monitoring and Notifications (VisioNize®) | VisioNize® touch enabled | VisioNize® touch enabled |

| Temperature range | 8 °C above ambient to 60 °C | 8 °C above ambient to 60 °C |

| Temperature accuracy | ±0.4 °C at 37 °C | ±0.4 °C at 37 °C |

|

Agitation |

||

| Orbit | 2.5 cm (1 in) | 5.1 cm (2 in) |

| Speed | 20 – 300 rpm | 20 – 250 rpm |

| Control increments | 1 rpm | 1 rpm |

| Control accuracy | ±1 rpm | ±1 rpm |

Applications

- Expansion of mammalian cells in suspension e.g., CHO or HEK293 for:

• Protein expression

• Screening

• Cell line development

• Early process development

• Viral vector production in mammalian cells e.g., Ad, AAV, LV

• Bioreactor inoculum preparation - MSC/iPSC-cultivation in normoxic conditions e.g., microcarrier-based for reprogramming or exosome production

Features

- Up to 40 % higher flask capacity: e.g., 8 x 5 L Corning®/Thomson Optimum Growth®, 25 x 1 L / 42 x 500 mL / 102 x 125 mL Erlenmeyer flasks (on sticky pad)

- 180 °C sterilization routine integrated: incl. wizard and downloadable performance protocol; no locally restricted UV-airflow/surface-disinfection

- Stainless steel chamber: Hygienic design according to EN ISO 14159:2008 standard plus only few internal parts and no drive wheel, crevices, cables or heating fins inside

- Optimized throughput per lab space: Highest platform size vs. footprint ratio in the market, stackable up to 3-fold

- Saves costs: Always included: slide-out platform, rH-control, touch interface, access port, 180 °C sterilization routine; no UV-lamps that require frequent exchange; low gas and energy consumption

- Eppendorf X-drive: Proven and tested shaker drive with four weight-supporting shafts for 24/7 vibration-free shaking

- Glide-up door and slide-out platform: Saves space and ensures fast and easy experiment setup, cleaning and service – even at the back of the chamber

- Full control and fast root-cause analysis: 7” touchscreen shows all setpoints and current parameters at a glance; direct visual overview of logged data/events incl. door openings and alarms, user management

- Accessories & options: Storage base and feet, various service options incl. IQ/OQ-GxP-service, VisioNize® Lab Suite remote monitoring and more

- Limited time special offer: One year free subscription to VisioNize® Lab Suite Sample Safety+ including SMS notifications, response-based alert escalation, audit trail and more – check availability of VisioNize in your country