The BioFlo 320 is highly configurable to suit your requirements

The BioFlo 320 offers the highest level of application flexibility, made possible by features like universal connections for analog and digital sensors, up to six integrated pumps, a highly configurable gas flow control, and compatibility with a wide range of glass and single-use bioreactors.

• Suitable for the cultivation of human and animal cells, including stem cells, as well as microbial fermentation.

• Supports batch, fed-batch, continuous, and perfusion mode.

• Suitable for many applications, including the production of cells, secreted proteins, viral vectors, plasmids, and small molecules.

The BioFlo 320 seamlessly connects R&D to production

The BioFlo 320 is compatible with a wide selection of glass and single-use bioreactors, providing working volumes from 400 mL to 40 L on a single platform. In combination with the BioFlo 720 bioreactor control system, the BioFlo platform supports one of the widest range of single-use solutions, allowing the scale-up of your process to up to 2,000 L.

• Integrated Scale Up Assist software feature simplifies the calculation of important process parameters necessary to scale up and down.

• Documentation packages are available to support controller qualification in GMP-regulated processes.

• Emerson® DeltaV integration with the BioFlo 320 simplifies tech-transfer, scale-up, and recipe sharing.

Integrated software assistants save time and mitigate risks

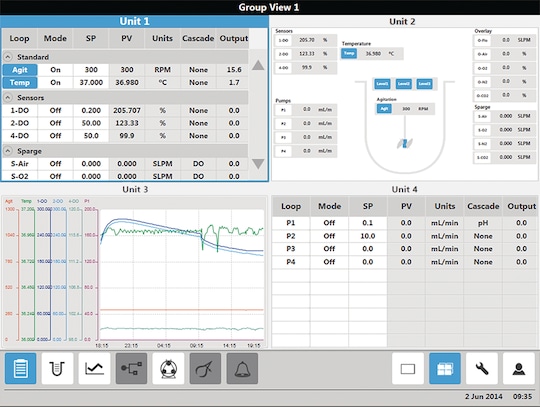

Monitoring the controller and the process is key to successful process development. The BioFlo 320 software is designed to provide you with the status of both.

• Alarm functions automatically inform about the status of the process.

• The diagnostic screen provides information on the hardware status and upcoming maintenance.

• Auto Calibrate – automatic calibration of all connected DO sensors at once reduce preparation time and ensures consistency.