CryoCube® F740 Series - ULT Freezer

Eppendorf CryoCube F740hi ULT freezer: External certification

Eppendorf CryoCube® F740 ULT freezer: Interface

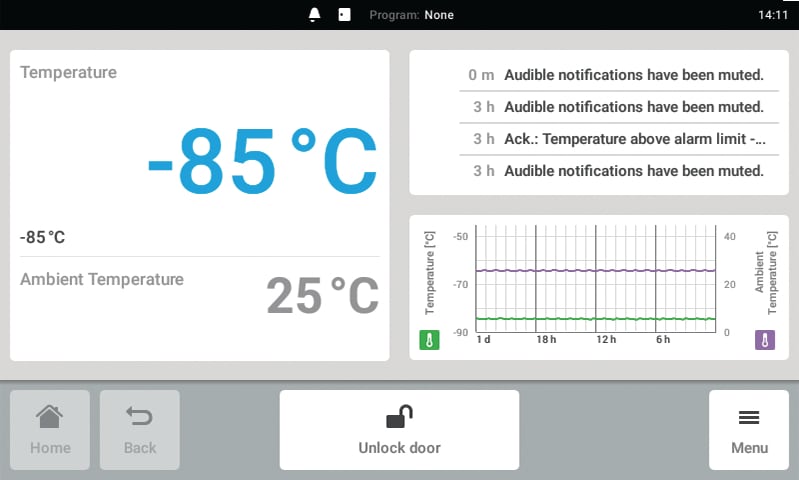

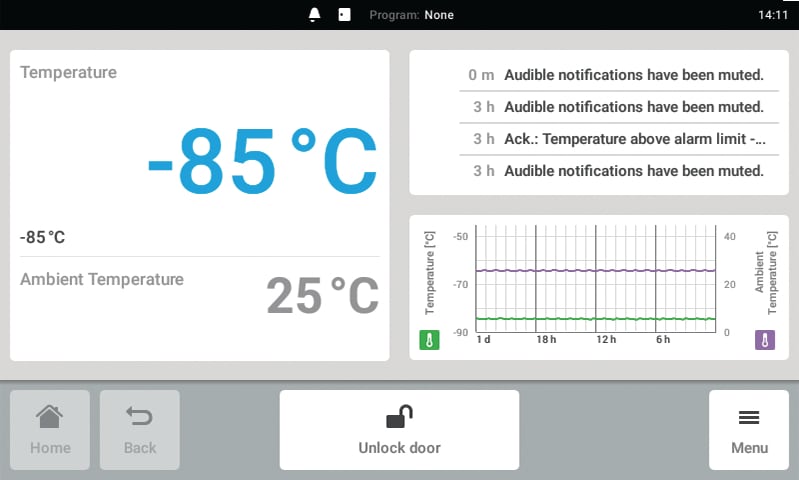

Eppendorf CryoCube® F740hi ULT freezer: Display

Eppendorf CryoCube® F740 ULT freezer: Home screen

Eppendorf CryoCube ULT freezer: Door handle

Eppendorf CryoCube ULT freezer: Door handle

Eppendorf CryoCube® F740h ULT freezer: Angled view

Eppendorf CryoCube® F740 ULT freezer: 3 compartments

Eppendorf CryoCube® F740 ULT freezer: 3 compartments, racked

Eppendorf CryoCube® F740 ULT freezer: 5 compartment version

Eppendorf CryoCube® F740 ULT freezer: 5 compartments, racked

Eppendorf CryoCube® F740hi ULT freezer: Rear panel

CryoCube F570 automatic vent port, detail

Eppendorf CryoCube® F740 ULT freezer: Door seals

Inner door of ULT freezer

Eppendorf CryoCube F740 ULT freezer: Filter compartment

Silence requested?: Filter position reduces noise level of CryoCube F740 series

Eppendorf CryoCube F740 ULT freezer: Shelves with airways

Eppendorf CryoCube F740 ULT freezer: Lockable power switch

ULT freezer with barcoded sample tube

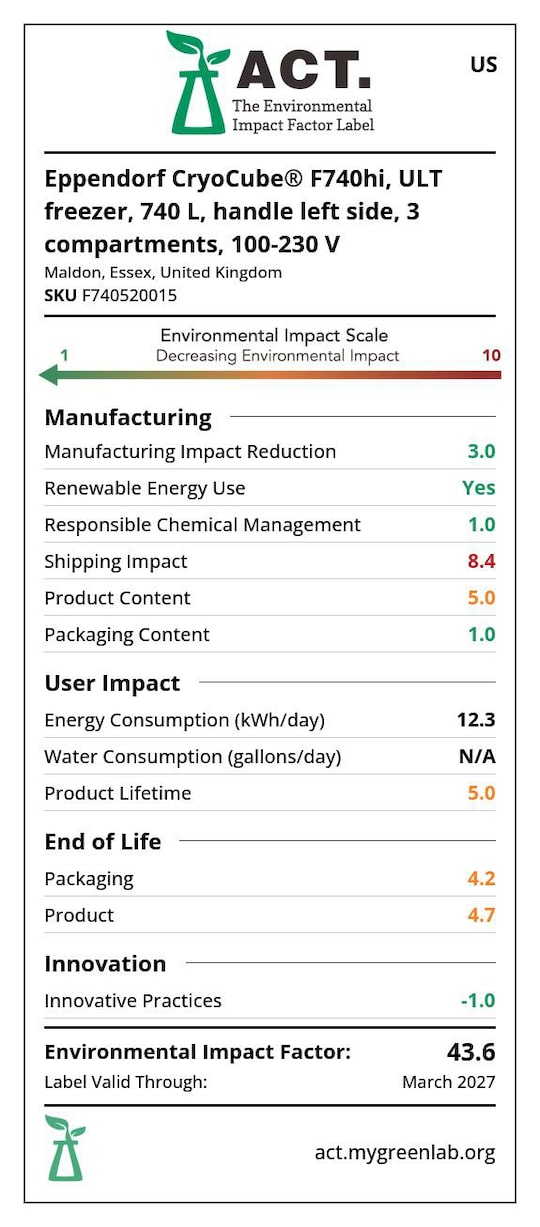

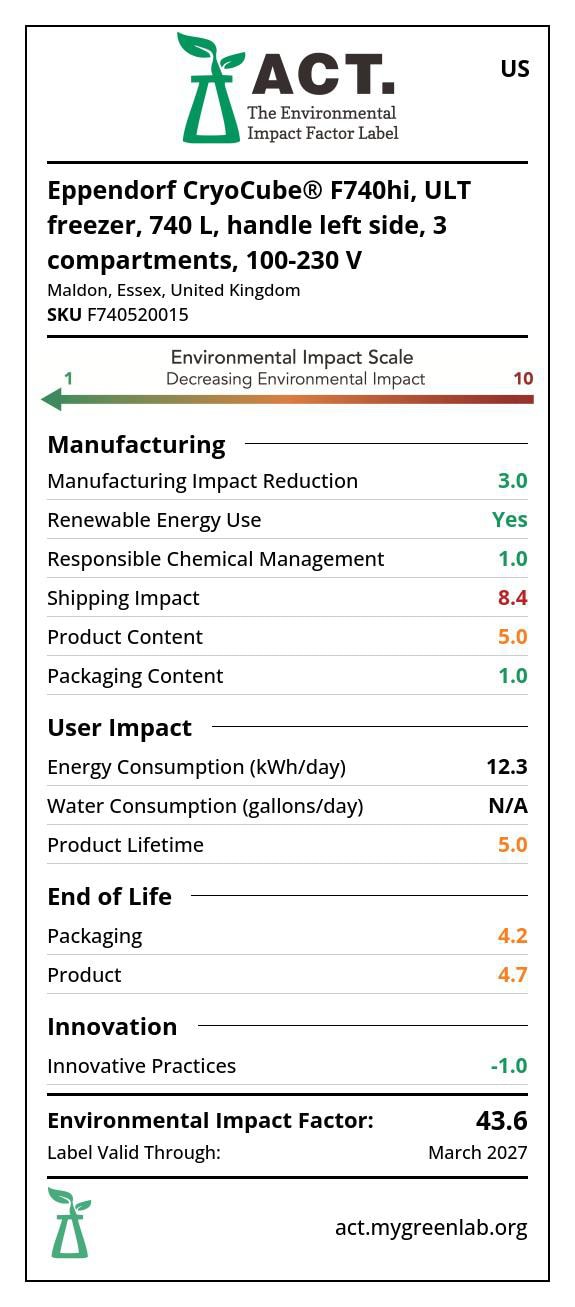

Eppendorf CryoCube F740hi ULT freezer: ACT label

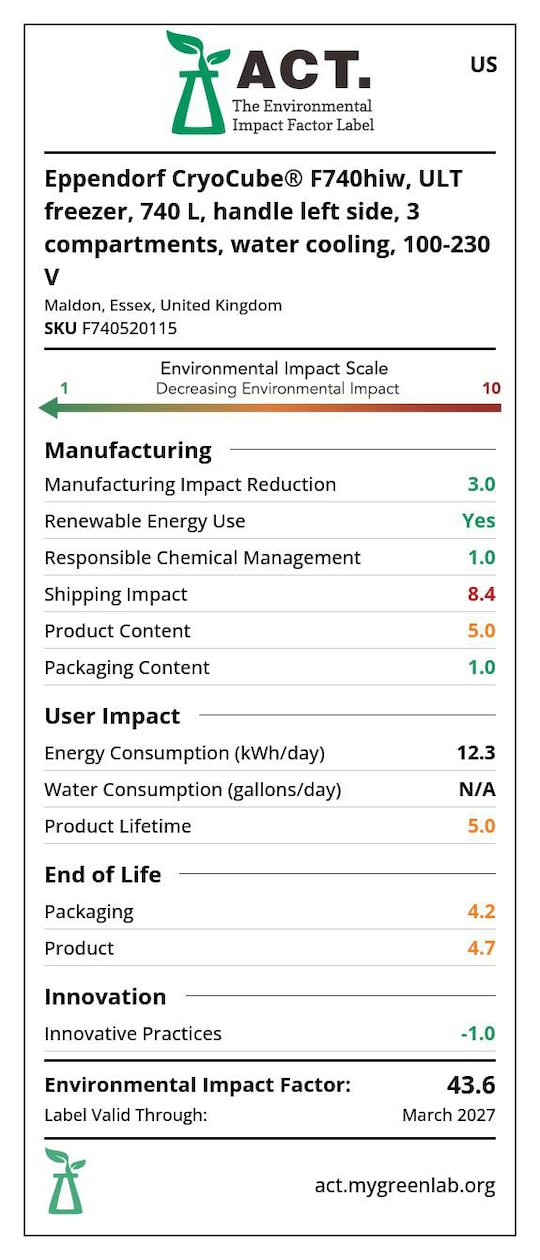

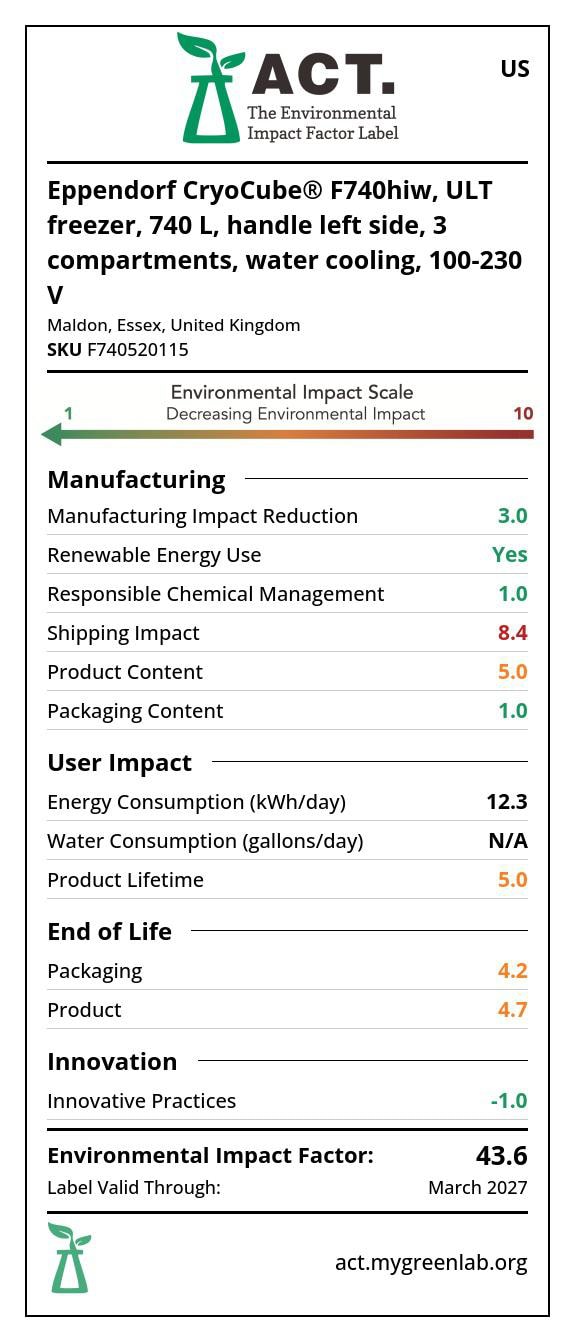

Eppendorf CryoCube F740hiw ULT freezer: ACT label

CryoCube F740hi benefits

Videos not loading, because cookies have been rejected. Change your

Product Information

Design the freezer around the sampleThe Eppendorf CryoCube® F740 series is one of the latest additions to the Eppendorf ULT Freezer family (also known as ultra-low temperature freezer, -80°C). Combining the high-quality tradition of our previous freezers with an increased capacity, the CryoCube F740 series ULT freezer is designed to store more of your samples securely while maintaining optimal energy usage. The integration of the PhysioCare Concept® during development means that the CryoCube F740 is easier and more comfortable to use, supports an ergonomic workspace, and enables an optimal workflow in the lab.

CryoCube F740

You will find additional download material at the bottom of this page

Single Devices (10)

Services (9)

Accessories (4)

10 Single Devices

|

Catalog no.

F740320134

|

|

|

|

|

|

|

|

|

Show more Products

Product Information

Technical Data

Applications

Features

Product Information

How can I find the best fitting ULT freezer for my needs? Please select the best fitting lab freezer:

CryoCube F740h:

80 mm wall (polyurethane foam and vacuum insulation panels), LED interface, "green" cooling liquids (R290/ R170), and air-cooling

CryoCube F740hi:

80 mm wall (polyurethane foam and vacuum insulation panels), touchscreen interface, "green" cooling liquids (R290/ R170), and air-cooling

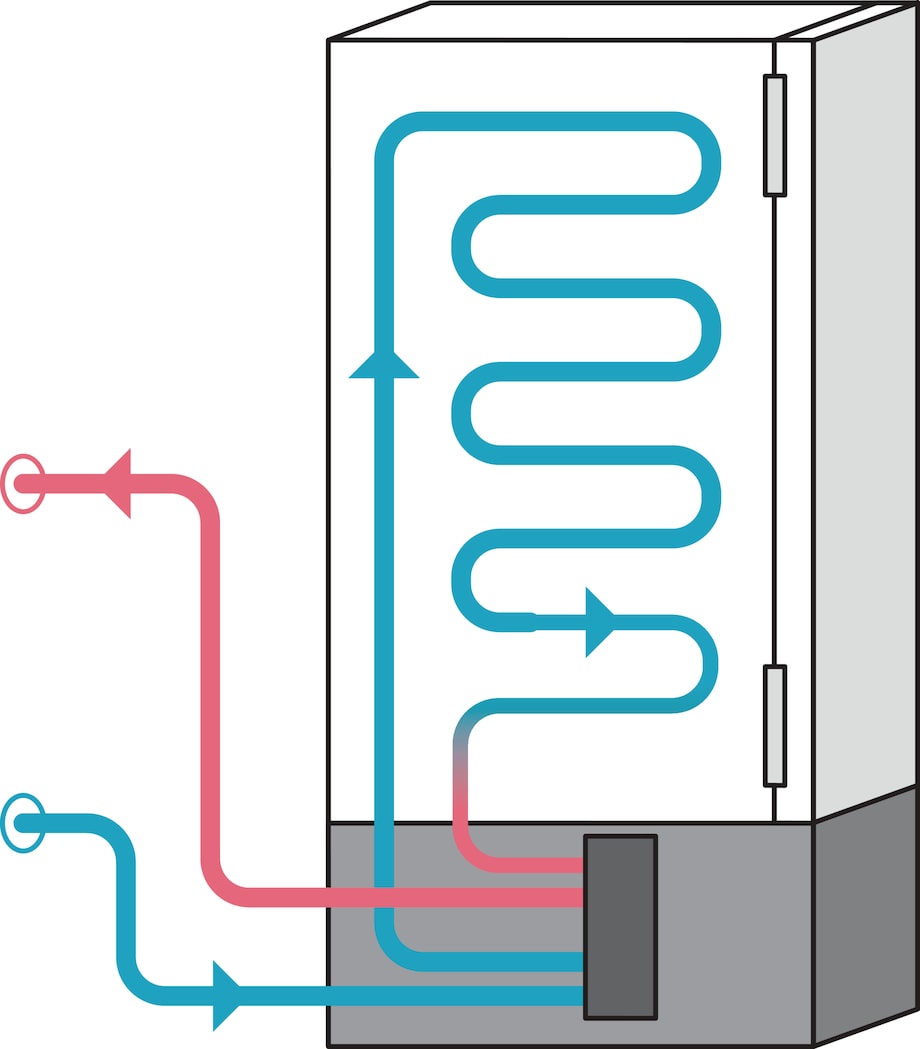

CryoCube F740hiw:

80 mm wall (polyurethane foam and vacuum insulation panels), touchscreen interface, "green" cooling liquids (R290/ R170), and water-cooling

All -80°C lab freezer versions of the CryoCube F740 series have a volume of 740 L (26.1 cubic feet), store up to 576x freezer boxes, and provide a temperature range from -50 °C to -86 °C.

Eppendorf ULT freezers are known for their energy efficiency, reliability, and worry-free, long-term sample preservation.

Worried about the safety of valuable samples in your ULT freezer?

The "i" versions are equipped with a touchscreen interface where data are stored on-board and can be checked 24/7. If necessary, data as well as service reports can be extracted by a front-mounted USB port. The electronic lock system enables controlled access and higher sample safety.

This handling concept is based on our long-term expertise from Eppendorf PhysioCare® combined with extensive user test sessions.

The CryoCube F740 series is equipped with reliable heavy-duty compressors (2-stage cascade cooling system). Quick pull-down times (250 min) enable fast re-use after cleaning/defrosting of the instrument. The freezers have short recovery times after opening to provide extra sample safety.

For even higher sample safety, the ULT freezers can be equipped with CO2/LN2 back-up systems and a chart recorder (Type II). Temperature monitor systems can be used to monitor the freezers remotely.

It’s 2 a.m. in the morning & and the phone rings...

»There is an alarm in your lab, you‘d better come over…«

Due to the 50,000 valuable samples in your freezer, you rushed to the lab. Finally, the temperature was still ok, false alarm but you were done for the day.

Just imagine, you get an alarm notification of VisioNize by email about your freezer, and in the next step, you log into the system and check online the temperature graph and the events of your freezer – still being at home. Then, you can still decide if you have to go to the lab or if you still have some hours - or if it is again a false alarm.

Your freezer becomes a smart storage with VisioNize keeping your valuable samples safe.

VisioNize offers you the possibility to remotely monitor your freezer. Take advantage of customizable notifications to meet your needs. More peace of mind for "You and Your Lab" with VisioNize.

Learn more about VisioNize

Important note:

Depending on your country, VisioNize and the VisioNize services may not be available. You can either check the Eppendorf eShop or contact your Eppendorf sales representative for details.

Bothered by loud ULT freezers?

The CryoCube F740h has an improved sound level of 47.8 dB. The "i" versions provide you some silence level of even down to 41.3 dB. These "i" versions are equipped with a sound-reduction system. Based on a different air filter position at the front of the freezer, the air flow is now guided in a more silent way towards the ventilation system. At the back of the freezer, a special compartment further reduces the sound level. Relax when working near a CryoCube F740 "i" version.

Burdened by unsorted boxes cluttering your freezer?

Make your scientific life easier: Store your freezer storage boxes within organized freezer racks. The CryoCube F740 series offers two different ways to store boxes: The 3-compartment and the 5-compartment style.

• A maximum of 576 boxes can be stored in a 3-compartment CryoCube F740 equipped with MAX racks or 504 boxes equipped with standard racks.

• The 5-compartment CryoCube F740 can be used for up to 528x boxes.

For other racking systems, please check the inner dimensions of the freezer and contact Eppendorf.

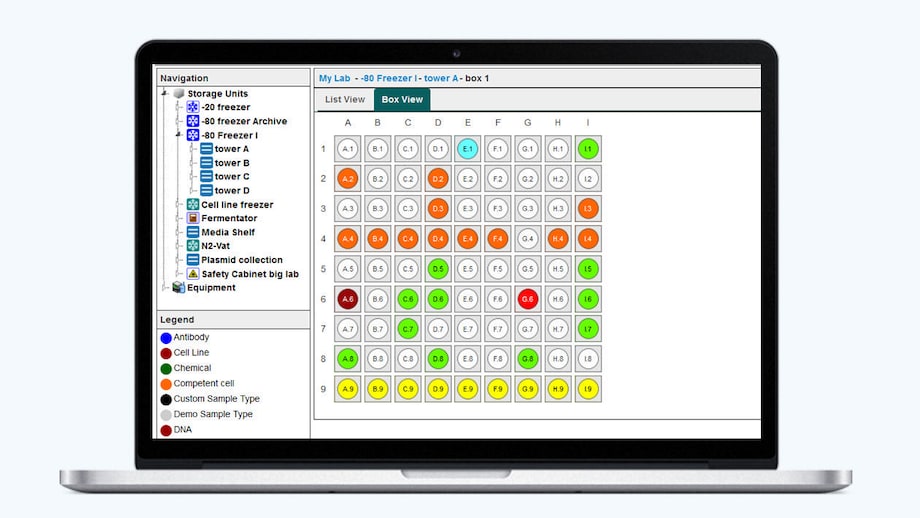

Additionally, you might think about a sample management solution beyond sample location documentation by paper or spreadsheet. Check out eLabInventory software.

Need a special set-up?

All units are available with 3 or 5 compartments:

• The 3-compartment unit has 3 shelves (fixed bottom one + two removable shelves).

• The 5-compartment unit has 5 shelves (fixed bottom one + 4 removable shelves).

• The shelves can be re-arranged by using the rails at the walls.

• All models (3 as well as 5 compartment versions) are equipped with 3 inner doors by standard. The positions of these doors are fixed.

The air-cooled versions offer a left-handed or right-handed outer door handle as an option to adapt the freezer to the conditions in your lab.

The built-in inverter technology enables the same freezer to be used on 100, 115, 208, and 230 V, just change the power cable.

Focusing on sustainability?

The "h" versions are the green flagships - by using hydrocarbon-based cooling liquids (R290/ R170), the power consumption is further reduced compared to classic cooling systems.

CryoCube F740 models are also validated by the ACT® concept of "My Green Lab®".

The CryoCube F740hi and F740hiw are certified by ENERGY STAR®.

Learn more about sustainability at Eppendorf

Support the epGreen initiative with your Eppendorf ULT freezer

Eppendorf Ultra-Low Temperature freezers are among the most energy-efficient in the industry, reducing energy consumption by thousands of kilowatt hours over our competition.

Factors influencing the energy consumption

• Thickness of insulation

• Type of insulation

• Type of cooling liquid

• Efficiency of compressors

• Control of compressor

• Pressure in cooling system

• Style of cooling loops (diameter, length, density,..)

• Sealings of outer door

• Sealings of inner doors

• Insulation of inner doors

• Insulation of outer door

Our part for sustainability

• Production moved into new building with state-of-the-art building insulation to save heating energy and power

• Assembled with 100% renewable electric power

• Heat output during final individual unit testing discharges building heating system

• Plastic and cardboard compactors introduced + waste rebate system in place

• Local requirements for waste management (collection of electronic waste like circuit boards, recycling via authorized recycling organizations) and internal guide lines

• Usage of green cooling liquids in Eppendorf ULT freezers for 13 years

• Packaging parts have increasing share of recycled origin

• Packaging is more than 99% recyclable (wood, cardboard, PE-foil)

• REACH + RoHS compliant

• ENERGY STAR® partner

• Marketing material is printed on certified paper, wherever possible focus on pdf only

• Shipment by cargo ship to reduce CO2 footprint

Hydrocarbons

In 2014, the European Union announced a ban of all non-hydrocarbon-liquids (EU_517/2014) until 2020 (also known as "F-gas regulation").

Hydrocarbons are also known as green or natural gases. The two major representatives are propane and ethane (known as R290 and R170). Based on IEC 60335-2-89, there are no additional safety instructions for using green gases in ULT freezers necessary.

This ban includes all cooling devices except instruments for temperatures below -50°C. Based on this exception, ULT freezers of -86°C can continue to run with HFCs. Still, it makes sense to replace the HFC cooling liquids also for ULTs as global warming needs to be slowed down.

Due to this goal, we at Eppendorf clearly plan to replace all classic cooling ULT freezers within the next years.

Remember 2008?

As being one of the very first movers for green gases at -86°C, Eppendorf has now more than 13 years of experience in R&D, production, logistics, and service in the field.

In 2008, the (Eppendorf) New Brunswick Premium U570h was one of the very first commercially available ULT freezers driven by green cooling liquids.

Green CryoCube® F740 series

A major step is done by focusing the flagship CryoCube® F740 series on future-proof green cooling liquids only: The CryoCube F740h, the F740hi, and the water-cooled F740hiw.

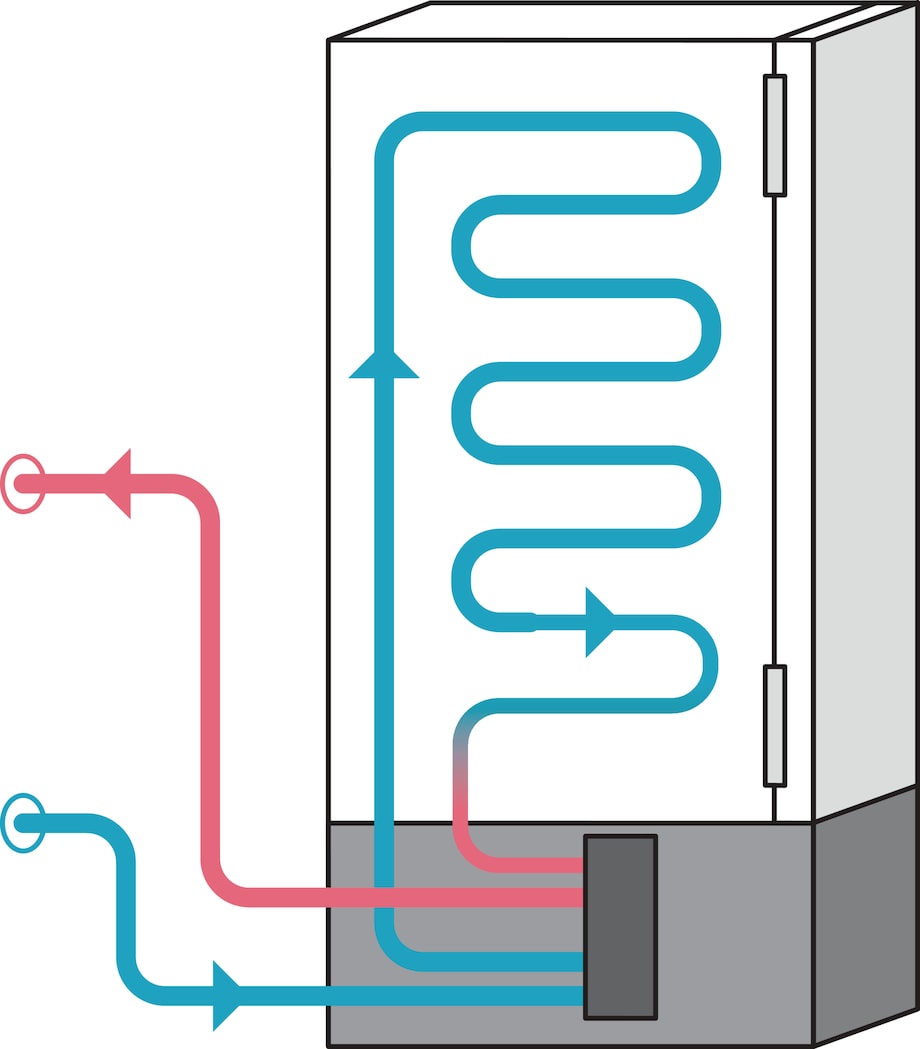

Air-conditioning at the limit? Go for water-cooling

You can improve the conditions and comfort in your lab while saving energy by installing a water-cooled Eppendorf freezer. Many ULT freezers use the air in the laboratory to extract heat energy from the freezer’s heat exchanger. Another option is to use a water-cooled ULT freezer connected to a facility’s recirculating water system. A constant stream of water removes the heat from the heat exchanger, rather than the ambient air in the lab.

• Reduce air conditioning power consumption by letting the water carry away the heat

• The heated cooling water can be reused for other heat demanding systems in the facility

System specifications:

• Minimum flow: 29 L/h

• Inlet pressure: 1 – 10 bar

• Temperature range of water: 7 °C to 25 °C

Annoyed by uncomfortable handling?

Ergonomics is far beyond the »ergonomically designed chair«. Eppendorf started to optimize the laboratory devices regarding ergonomics already in the early 1970s.

In 2003, we started the PhysioCare® Concept, focusing on ergonomic liquid handling devices like our pipettes.

Nowadays, the Eppendorf PhysioCare Concept is broaden up to include further laboratory products as a holistic solution to harmonize the workflow in your laboratory with your health and well-being, e.g. for the Eppendorf ULT freezer:

• Intuitive interface for easy handling

• Automatic vent port for easy re-access to samples

• Low noise level for convenient working conditions

• Ergonomic door handle for easy opening and closing

• All cable interfaces are located at one corner for convenient access

Further information about the Eppendorf PhysioCare Concept:

www.eppendorf.com/physiocare/

Lost in samples? Stay organized!

Over many years, you collect hundreds and thousands of samples – samples that are the results of years of hard work – samples of high value. When storing these in the ULT freezer at -80°C, it is vital to keep them safe and accessible.

Many scientists still use spreadsheets or even paper-based lists to keep track of their storage. While these solutions may work most of the time, they are susceptible to human error, damage, and misplacement.

Keep track of your samples with eLabInventory

eLabInventory is a sample management software.

Start a free 30-day trial!

Visit www.eLabInventory.com

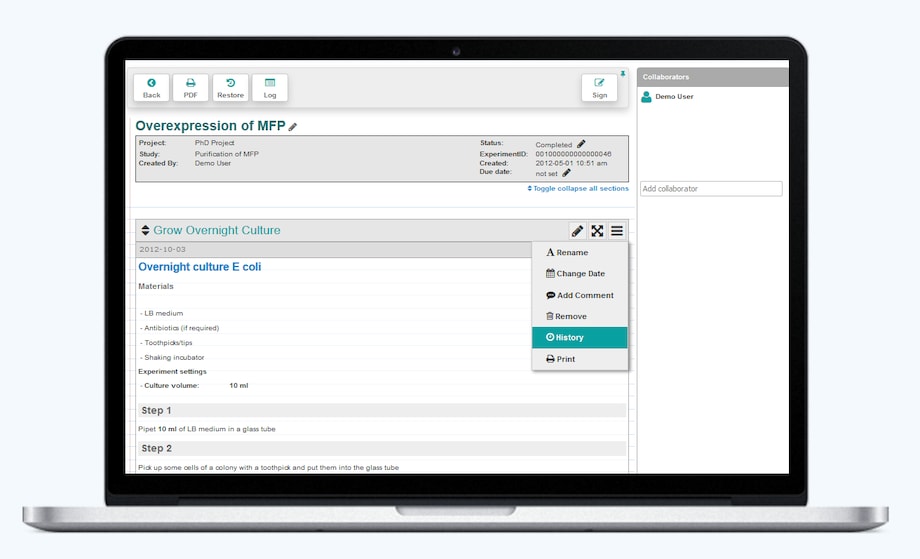

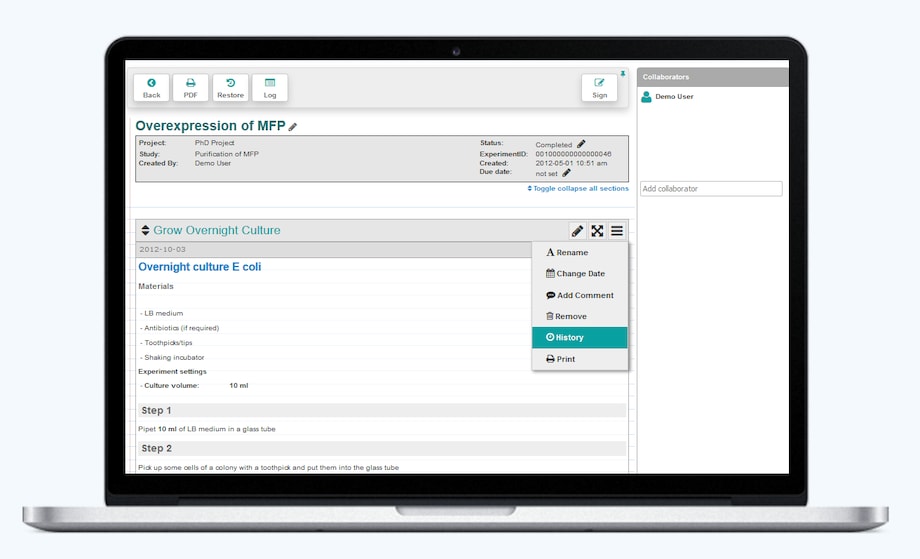

Struggling with paper-based documentation?

The eLabJournal Electronic Lab Notebook offers an intuitive and flexible solution to document research and track research data like workflow processes where the ULT freezer is involved. Improve efficiency when documenting, organizing, searching, and archiving collected data. With the free eLabJournal add-ons, you can extend the functionality of eLabJournal to a fully integrated Laboratory Information Management System.

Start a free 30-day trial!

Visit www.eLabJournal.com

Efficient lab and device management with VisioNize® Lab Suite

Are you interested in monitoring your lab devices and receiving notifications e.g., for device alarms? A digital, connected lab offers even more.

Gain access to a modular range of digital services and choose what works for your lab. VisioNize Lab Suite offers everything you need as a Lab Manager or Scientist to get started to digitally manage your lab for increased sample security, compliance needs and maintenance management.

Chart your own course to digital lab excellence! Find out more

End-of-Life

Disposal of packaging

The packaging of the ULT freezer contains different materials, this includes a wooden pallet, cardboard, a plastic dust cover, and some foam parts. Recycling of materials becomes more and more important every day: Are you aware that nearly all cardboard material is recycled in Europe? Our freezer packaging cardboard material consists of ca. 70% recycling material. Please support the global sustainability initiative of recycling valuable raw material by also collecting the freezer cardboard packaging material and disposing of it in the appropriate collection container at your organization. In respect to the plastic dust cover made of LD-PE and the foam parts, we recommend to select a dedicated recycling partner where PE material can be recycled. We suggest you contact your local waste hauler or facility management team to understand the available recycling options for your organization.

Disposal of instrument

Our freezers last for many years, but if they need to be replaced, we kindly ask you to fulfill local requirements for disposal of these instruments. We strongly recommend a certified local recycling partner with experience in instruments with active cooling. Keeping it “local“ reduces the impact of transportation, and the „certified“ aspect is recommended due to the safe and sustainable removal and recycling of the cooling liquids.

Decontamination

This piece of equipment was used in a laboratory and/ or was used to handle biological samples. Please keep in mind to adequately decontaminate the equipment which needs to be disposed. Check local requirements. For more information, get in contact with your local biosafety officer and/ or waste officer. Check if your local recycling partner has special instructions and/ or documentation requirements. You may also use the Eppendorf decontamination form sheet as guidance.

Read More

Read Less

Technical Data

| Specifications | CryoCube® F740hi, 3 c. | CryoCube® F740hi, 5 c. | CryoCube® F740hiw, 3 c. | CryoCube® F740hiw, 5 c. | CryoCube® F740h, 3c. | CryoCube® F740h, 5c. |

|---|

| ACT label | yes | yes | yes | yes | − | − |

| Cooling type | air cooling | air cooling | water cooling | water cooling | air cooling | air cooling |

| Cooling liquid | green cooling liquids (R290 / R170) | green cooling liquids (R290 / R170) | green cooling liquids (R290 / R170) | green cooling liquids (R290 / R170) | green cooling liquids (R290 / R170) | green cooling liquids (R290 / R170) |

| Heat output | 438 W | 438 W | 442 W | 442 W | 492 W | 492 W |

| Insulation | vacuum insulation paneling / polyurethane foam | vacuum insulation paneling / polyurethane foam | vacuum insulation paneling / polyurethane foam | vacuum insulation paneling / polyurethane foam | vacuum insulation paneling / polyurethane foam | vacuum insulation paneling / polyurethane foam |

| Capacity | 740 L (26.1 ft³) | 740 L (26.1 ft³) | 740 L (26.1 ft³) | 740 L (26.1 ft³) | 740 L (26.1 ft³) | 740 L (26.1 ft³) |

| No. of compartments | 3 | 5 | 3 | 5 | 3 | 5 |

| No. of internal doors | 3 | 3 | 3 | 3 | 3 | 3 |

| Max. racks per freezer | 18 | 30 | 18 | 30 | 18 | 30 |

| Noise level | 41.3 dB | 41.3 dB | 41.3 dB | 41.3 dB | 47.8 dB | 47.8 dB |

| High-Efficiency | yes | yes | yes | yes | yes | yes |

| Power supply | 230 V, 50 Hz | 230 V, 50 Hz | 230 V, 50 Hz | 230 V, 50 Hz | 230 V, 50 Hz | 230 V, 50 Hz |

| Max. power consumption | 10500 W | 10500 W | 10600 W | 10600 W | 11800 W | 11800 W |

| Average Daily Consumption (230 V) | 10.5 kWh/day | 10.5 kWh/day | 10.6 kWh/day | 10.6 kWh/day | 11.8 kWh/day | 11.8 kWh/day |

| Average Daily Consumption (208 V) | 10.5 kWh/day | 10.5 kWh/day | 10.6 kWh/day | 10.6 kWh/day | 11.8 kWh/day | 11.8 kWh/day |

| Average Daily Consumption (115 V) | 11.6 kWh/day | 11.6 kWh/day | 11.7 kWh/day | 11.7 kWh/day | 13 kWh/day | 13 kWh/day |

| Dimensions (W × D × H) | 111 × 98.0 × 197.3 cm / 43.7 × 38.6 × 77.7 in1)2)3) | 111 × 98.0 × 197.3 cm / 43.7 × 38.6 × 77.7 in1)2)3) | 111 × 98.0 × 197.3 cm / 43.7 × 38.6 × 77.7 in1)2)3) | 111 × 98.0 × 197.3 cm / 43.7 × 38.6 × 77.7 in1)2)3) | 111 × 91.3 × 197.3 cm / 43.7 × 36 × 77.7 in1)2)3) | 111 × 91.3 × 197.3 cm / 43.7 × 36 × 77.7 in1)2)3) |

| Shipping weight | 364 kg / 787 lb | 382 kg / 806 lb | 369 kg / 787 lb | 377 kg / 806 lb | 357 kg / 787 lb | 366 kg / 806 lb |

| Product weight | 315 kg / 694 lb | 333 kg / 734 lb | 320 kg / 705 lb | 328 kg / 723 lb | 308 kg / 679 lb | 317 kg / 699 lb |

| Temperature range | -50 °C to -86 °C | -50 °C to -86 °C | -50 °C to -86 °C | -50 °C to -86 °C | -50 °C to -86 °C | -50 °C to -86 °C |

| Access port | 2 | 2 | 2 | 2 | 2 | 2 |

| Remote Device Monitoring and Notifications (VisioNize®) | VisioNize® touch enabled | VisioNize® touch enabled | VisioNize® touch enabled | VisioNize® touch enabled | VisioNize® box enabled | VisioNize® box enabled |

| Pull-down time to -80 °C | 4 h 10 min4) | 4 h 10 min4) | 4 h 10 min4) | 4 h 10 min4) | 4 h 10 min4) | 4 h 10 min4) |

|

Box capacity per freezer |

||||||

| 53 mm (2 in) tall boxes | 576 | 528 | 576 | 528 | 576 | 528 |

| 64 mm (2.5 in) tall boxes | 432 | 408 | 432 | 408 | 432 | 408 |

| 76 mm (3 in) tall boxes | 360 | 288 | 360 | 288 | 360 | 288 |

| 102 mm (4 in) tall boxes | 288 | 264 | 288 | 264 | 288 | 264 |

| 127 mm (5 in) tall boxes | 216 | 48 | 216 | 48 | 216 | 48 |

|

DWP capacity per freezer |

||||||

| 102 mm (4 in) tall boxes | 864 | 792 | 864 | 792 | 864 | 792 |

|

Box capacity per rack |

||||||

| 53 mm (2 in) tall boxes | 32 | 16 | 32 | 16 | 32 | 16 |

| 64 mm (2.5 in) tall boxes | 24 | 12 | 24 | 12 | 24 | 12 |

| 76 mm (3 in) tall boxes | 20 | 8 | 20 | 8 | 20 | 8 |

| 102 mm (4 in) tall boxes | 16 | 8 | 16 | 8 | 16 | 8 |

| 127 mm (5 in) tall boxes | 12 | 8 | 12 | 8 | 12 | 8 |

| DWP | 48 | 24 | 48 | 24 | 48 | 24 |

|

Included |

||||||

| CO2 backup system | no | no | no | no | no | no |

| LN2 backup system | no | no | no | no | no | no |

| Chart recorder | no | no | no | no | no | no |

1)Optional CO2/LN2 backup systems add 8.65 cm/3.5 in to height.

2)To allow for handles and hinges, add 80 mm to width of upright freezers and 110 mm to the depth of chest freezers.

3)Door open adds up to 15 cm.

4)Empty freezer with shelves fitted, upright freezers only, pull down from 21 – 23 °C ambient conditions.

Applications

- ULT freezers are suitable for storage and preservation of all types of biological materials/samples:

• Bacteria

• Cells

• Spores

• Pollens

• Protozoa

• Blood components (research only)

• DNA

• Tissue used in research only

• Preservation of chemicals or material testing components for a longer period of time

Features

- Traditionally foamed polyurethane insulation enforced by vacuum insulation panels in freezer body and door ("i" versions) provides efficient insulation protection

- Quick pull-down and recovery times with reliable heavy-duty compressors for sample safety

- Left- or right-handed outer door as option for optimal space usage in the lab

- Easy-to-read, eye level, flush mounted control panel and alarm status

- Inner doors are insulated and sealed, minimizing cold air loss while accessing your samples

- 3 or 5 compartments as option, each accepts Eppendorf racks as well as other popular brands without adjustment

- Each shelf has air slits for fast temperature adaption

- Special low-temperature outer door seals allow gaskets to remain flexible at -86 °C and prevents ice buildup

- Full stainless steel interior for easy cleaning during maintenance and defrost cycles; powder-coated steel exterior