MENU

FI | EUR

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Medlab Middle East 2025

- Biologics World Nordics 2025

- Bioprocessing Summit Europe 2025

- BioProcess International Europe 2025

- ASIA LABEX: The Lab Show 2025

- SLAS International 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Medlab Middle East 2025

- Biologics World Nordics 2025

- Bioprocessing Summit Europe 2025

- BioProcess International Europe 2025

- ASIA LABEX: The Lab Show 2025

- SLAS International 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

FI | EUR

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

No results found

Search Suggestions

DASware® control plus

Product Information

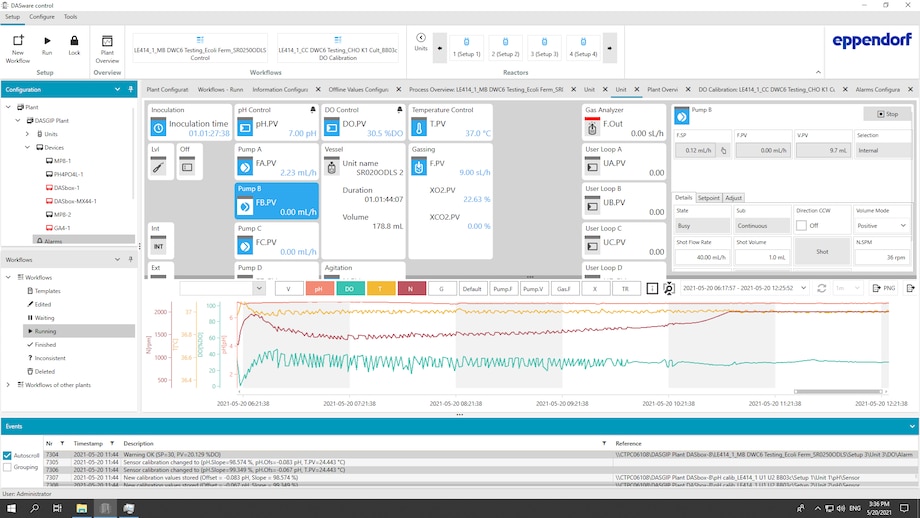

DASware control plus is a bioprocess SCADA software with 21 CFR Part 11 and EudraLex Volume 4 Annex 11 compatibility for use in clinical and commercial manufacturing. It can be used for bioprocess control using the Eppendorf bioreactor control systems, such as the bench-scale BioFlo 320 controller. DASware control plus enables individual monitoring and control of parallel bioprocesses, process automation, and advanced data analysis, providing maximum performance from experimental design to result. It offers functionalities tailored to streamline electronic record management, secure electronic signatures, and audit trail integrity.You will find additional download material at the bottom of this page

Products (1)

1 Products

|

|

Show more Products

Added to Your Cart

Product Information

Features

Product Information

DASware control plus: purpose-built with a focus on compatibility to 21 CFR Part 11 and EudraLex Volume 4 Annex 11, assisting users to achieve regulatory compliance with criteria set forth by those standards.

• User authentication and access control: aligning with the GMP requirements to prevent unauthorized access and maintain data integrity.

• Electronic records: track and document critical action in an audit trail, gaining a comprehensive view of data integrity and compliance history.

• Electronic signatures with confidence: ensure the authenticity and reliability of critical documentation in your bioprocessing operations.

• Efficient data management: retrieval and storage of human and electronic system readable data whilst adhering to rigorous data integrity standards.

Bioreactor Systems and Software Solutions – Orchestrated for Bioprocess Control, Automation, and Analysis

DASware control is the central bioprocess software solution from Eppendorf. Beyond bioprocess monitoring and control, it enables the seamless integration of bioprocess systems, control software, data analysis tools, and automation solutions to form a complete upstream bioprocessing solution.

Key benefits

• Parallel process monitoring and control.

• Reduced complexity due to the use of one central software solution.

• Easy integration of devices such as third-party sensors.

• Simplified data sharing and improved data analysis through seamless connection to BioNsight® cloud software.

• User authentication and access control: aligning with the GMP requirements to prevent unauthorized access and maintain data integrity.

• Electronic records: track and document critical action in an audit trail, gaining a comprehensive view of data integrity and compliance history.

• Electronic signatures with confidence: ensure the authenticity and reliability of critical documentation in your bioprocessing operations.

• Efficient data management: retrieval and storage of human and electronic system readable data whilst adhering to rigorous data integrity standards.

Bioreactor Systems and Software Solutions – Orchestrated for Bioprocess Control, Automation, and Analysis

DASware control is the central bioprocess software solution from Eppendorf. Beyond bioprocess monitoring and control, it enables the seamless integration of bioprocess systems, control software, data analysis tools, and automation solutions to form a complete upstream bioprocessing solution.

Key benefits

• Parallel process monitoring and control.

• Reduced complexity due to the use of one central software solution.

• Easy integration of devices such as third-party sensors.

• Simplified data sharing and improved data analysis through seamless connection to BioNsight® cloud software.

Benefit from powerful bioprocess control

• Efficiency: parallel sensor calibration, intelligent recipe management, and enhanced scripting automation.

• Performance: up to 8/16/24 vessel parallel operation, powerful charting tool, and advanced data management.

• Flexibility: configurable views and user-defined functions; In-field hardware and software updates.

• Reliability: user management and data integrity, event log and alarm functions.

• Regulatory standards: Compatible to 21 CFR Part 11 and EudraLex Volume 4 Annex 11. If you require a bioprocess control software for R&D, discover DASware control.

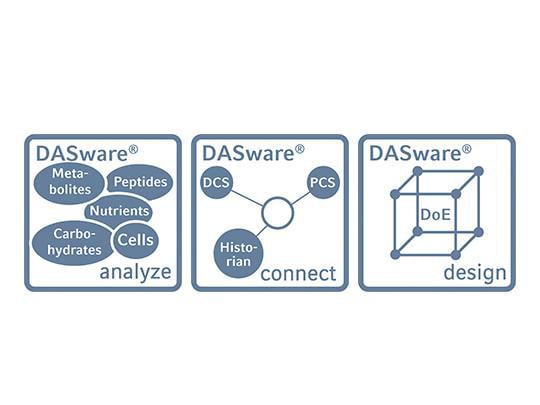

Expand your capabilities with the DASware software suite

DASware design, analyze, and connect are optional add ons to the DASware control SCADA software.

• Application of the Design of Experiments (DoE) concept via a full factorial DoE builder or by importing DoE designs from third-party DoE tools.

• Seamless integration of external lab devices to the bioreactor for process automation and feedback control loops.

• Integration into process control systems and legacy corporate historians for company-wide access to all relevant bioprocess data.

Your data is simply there

Bioprocess data can be seamlessly transferred from DASware control plus to BioNsight cloud software.

• Enables for remote monitoring and analytics.

• Enables data contextualization across devices, runs, and sites.

• Data preparation for AI-based analysis.

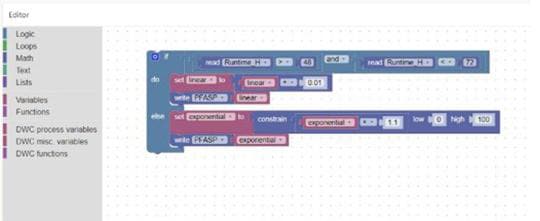

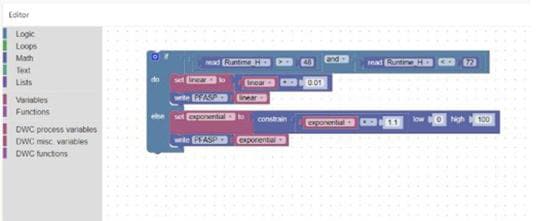

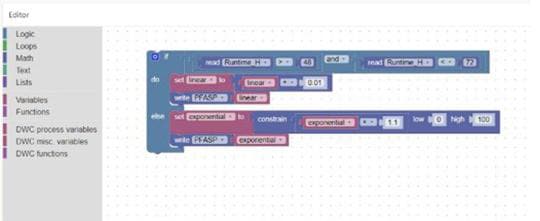

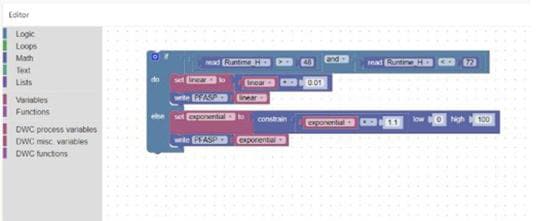

Easily customize your process control with graphical programming

• Ease of use: drag-and-drop interface allows users to create and modify workflows by linking functional blocks visually, reducing complexity compared to traditional scripting or coding.

• Improved accuracy: visual workflows help users spot logical or sequencing errors early, minimizing process disruptions and improving overall accuracy.

• Enhanced accessibility: users can quickly learn and deploy workflows, increasing operational efficiency and responsiveness to process changes.

• Transparency: automatic logging of all changes supports compliance, while revision histories allow for easy audits.

Read More

Read Less

Features

- Parallel process control with individual control of each vessel

- Integrated batch functionality for process and recipe management

- Ideally suited for Design of Experiments (DoE)

- Parallel calibration and cleaning procedures

- Customized views and user-defined functions

- Automated data export, reporting and chart creation for Microsoft® Excel®

- Professional database with managed access (Postgre SQL Server)

- OPC communication for easy integration with third-party equipment using DASware connect and DASware analyze

- Integrated analysis of offline values, online calculated values, and alarm notification

- Seamless connectivity and data transfer to BioNsight cloud

- IQ/OQ package available

Downloads: DASware® control plus

-

English