MENU

CH | CHF

-

-

-

- Services pour bioprocédés

- Services pour centrifugeuse et rotors

- Services pour Mastercycler

- Services pour automates de pipetage

- Services pour congélateurs

- Services pour incubateurs

- Services pour agitateurs

- Services pour appareils de photométrie

- Service de contrôle de la température et de l’agitation

- Service pour pipette

-

-

-

-

- Services pour bioprocédés

- Services pour centrifugeuse et rotors

- Services pour Mastercycler

- Services pour automates de pipetage

- Services pour congélateurs

- Services pour incubateurs

- Services pour agitateurs

- Services pour appareils de photométrie

- Service de contrôle de la température et de l’agitation

- Service pour pipette

-

CH | CHF

-

- Centrifugeuses de paillasse

- Centrifugeuses au sol

- Centrifugeuses réfrigérées

- Microcentrifugeuses

- Centrifugeuses multi-fonctions

- Centrifugeuses haute vitesse

- Ultracentrifugeuses

- Concentrateur

- Produits IVD

- High-Speed and Ultracentrifuge Consumables

- Tubes de centrifugeuse

- Plaques de centrifugeuse

- Gestion des appareils

- Gestion des échantillons et des informations

Aucun résultat trouvé

Chercher des suggestions

Bioprocess Autosampler

Bioprocess Autosampler dual head system, 4x DASbox, bottles side, front view, cropped

Bioprocess Autosampler:

Modulare Autosampling-Lösung für Bioprozesssysteme im kleinen und Labormaßstab

Modulare Autosampling-Lösung für Bioprozesssysteme im kleinen und Labormaßstab

Bioprocess Autosampler sample storage 1

Efficient sampling from bioreactors of different sizes. Different sample sizes with aseptic operation and low dead volume.

Gain Better Bioprocess Data with Less Effort

Les vidéos ne se chargent pas, car vous avez refusé les cookies. Changez vos

Informations produit

Le Bioprocess Autosampler prélève des échantillons de plusieurs bioréacteurs et les stocke ensuite à température tempérée pour les analyser plus tard. Il est compatible avec les bioréacteurs en verre et à usage unique fonctionnant avec une boucle d’asservissement pour bioréacteur DASbox® Mini Bioreactor System, DASGIP® Parallel Bioreactor System, SciVario® twin ou BioFlo® 320.Vous trouverez plus d’informations à télécharger au bas de cette page

Produits (2)

Services (4)

Accessoires (8)

2 Produits

Réf. catalogue

7700200007

|

Réf. catalogue

7700200008

|

Afficher plus de produits

Ajouté à votre panier

Informations produit

Applications

Caractéristiques

Informations produit

Obtenez plus facilement de meilleures données sur vos bioprocédés :

Vous devez souvent échantillonner votre culture au cours du bioprocédé, et pas seulement à la fin. Ces échantillons vous aident à contrôler la croissance, la formation des produits et la consommation de nutriments. De cette manière, vous pouvez identifier les interdépendances et prendre des mesures à des moments prédéfinis ou lors d’événements spécifiques, comme l’augmentation de l’OD après l’épuisement des sources de carbone. Le Bioprocess Autosampler d’Eppendorf vous apporte cette solution. Que vous travailliez dans le domaine de la culture cellulaire ou de la fermentation, au début de la R&D ou du développement de processus, et que vous utilisiez des bioréacteurs à usage unique ou des bioréacteurs en verre, ce système couvre tous les besoins. Le Bioprocess Autosampler peut prendre en charge l’échantillonnage et l’ajout de bolus à intervalles courts et réguliers, vous permettant d’obtenir des jeux de données complets et d’automatiser le contrôle des bioprocédés

Les avantages de l’échantillonnage automatique :

Les intervalles brefs et réguliers permettent d’obtenir des données complètes. Pour assurer le suivi complet d’un processus, vous avez besoin de mesurer régulièrement ses paramètres et de connaître le statut des cellules, ainsi que la concentration et la qualité du produit. Ces informations sont indispensables pour optimiser le processus.

Vous devez souvent échantillonner votre culture au cours du bioprocédé, et pas seulement à la fin. Ces échantillons vous aident à contrôler la croissance, la formation des produits et la consommation de nutriments. De cette manière, vous pouvez identifier les interdépendances et prendre des mesures à des moments prédéfinis ou lors d’événements spécifiques, comme l’augmentation de l’OD après l’épuisement des sources de carbone. Le Bioprocess Autosampler d’Eppendorf vous apporte cette solution. Que vous travailliez dans le domaine de la culture cellulaire ou de la fermentation, au début de la R&D ou du développement de processus, et que vous utilisiez des bioréacteurs à usage unique ou des bioréacteurs en verre, ce système couvre tous les besoins. Le Bioprocess Autosampler peut prendre en charge l’échantillonnage et l’ajout de bolus à intervalles courts et réguliers, vous permettant d’obtenir des jeux de données complets et d’automatiser le contrôle des bioprocédés

Les avantages de l’échantillonnage automatique :

Les intervalles brefs et réguliers permettent d’obtenir des données complètes. Pour assurer le suivi complet d’un processus, vous avez besoin de mesurer régulièrement ses paramètres et de connaître le statut des cellules, ainsi que la concentration et la qualité du produit. Ces informations sont indispensables pour optimiser le processus.

Prélèvement d’échantillon automatique

• Facilite le prélèvement 24/7 à des intervalles brefs et réguliers

• Libère du temps pour d’autres tâches

• Le stockage automatisé des échantillons réduit le risque d’erreur humaine

Procédure de prélèvement d’échantillon

• L’échantillonneur automatique pour bioprocédés dispose d’un port de prélèvement par bioréacteur

• Les tuyaux connectent le port de prélèvement à un tube d’immersion dans le bioréacteur

• Les ports de prélèvement disposent d’un septum qui garantit la stérilité du bioréacteur

• Pour le prélèvement d’échantillon, une aiguille connectée à une seringue est insérée automatiquement dans le port, traversant le septum

• L’échantillon est transféré vers une fiole en traversant un septum dans le capuchon de la fiole

Systèmes compatibles de contrôle des bioprocédés à petite échelle

Le Bioprocess Autosampler peut être installé sur de nouveaux systèmes de contrôle des bioréacteurs à petite échelle ou être adapté à des systèmes existants.

DASbox® Mini Bioreactor System

• Échantillonnage automatique de jusqu’à 16 bioréacteurs

• Compatible avec les bioréacteurs en verre et à usage unique

• Volume de travail : 60 à 250 ml

DASGIP® Parallel Bioreactor System

• Échantillonnage automatique de jusqu’à 16 bioréacteurs

• Compatible avec les bioréacteurs en verre et à usage unique

• Volume de travail : 200 mL à 1,8 L

Systèmes compatibles de contrôle des bioprocédés à l’échelle de laboratoire

Le Bioprocess Autosampler peut être installé sur de nouveaux systèmes de contrôle des bioréacteurs à l’échelle du laboratoire ou être adapté à des systèmes existants.

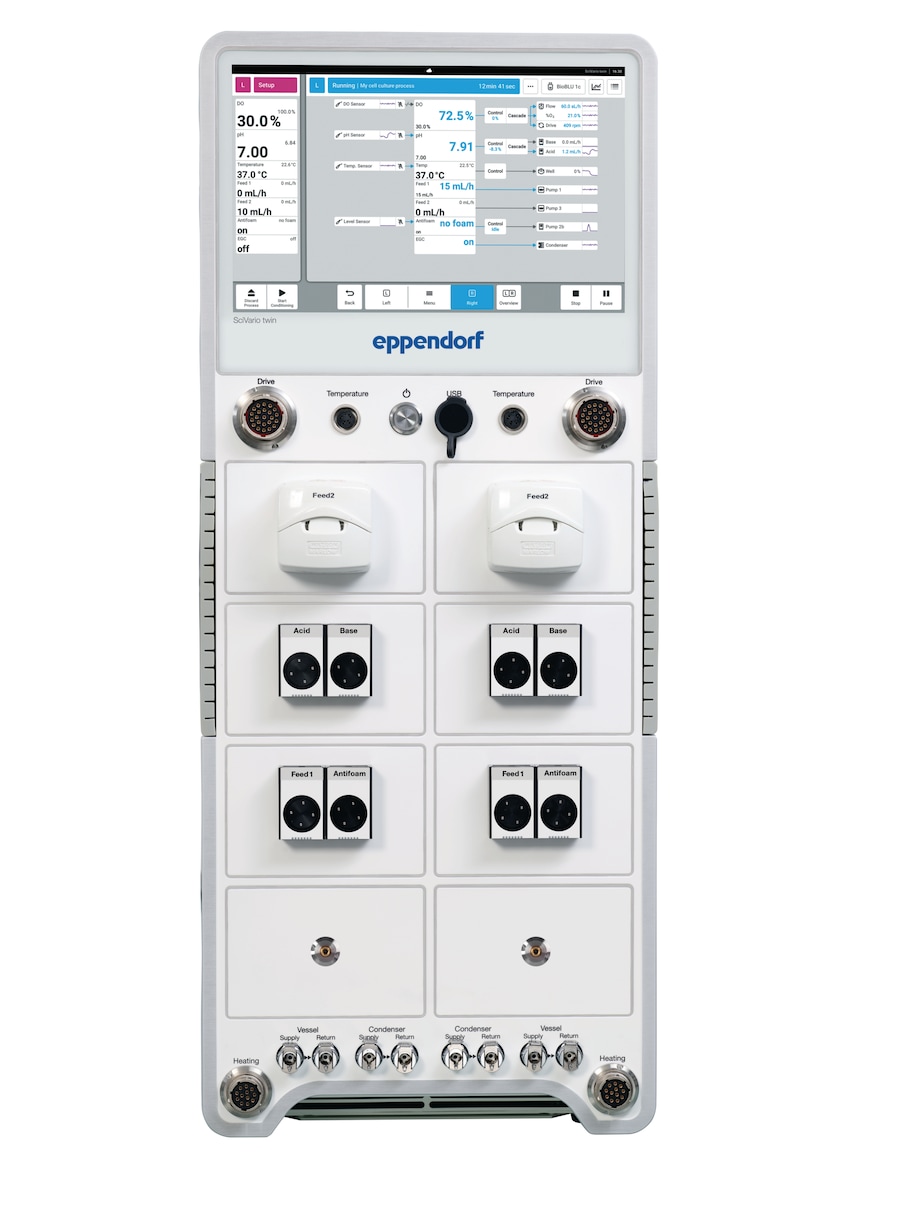

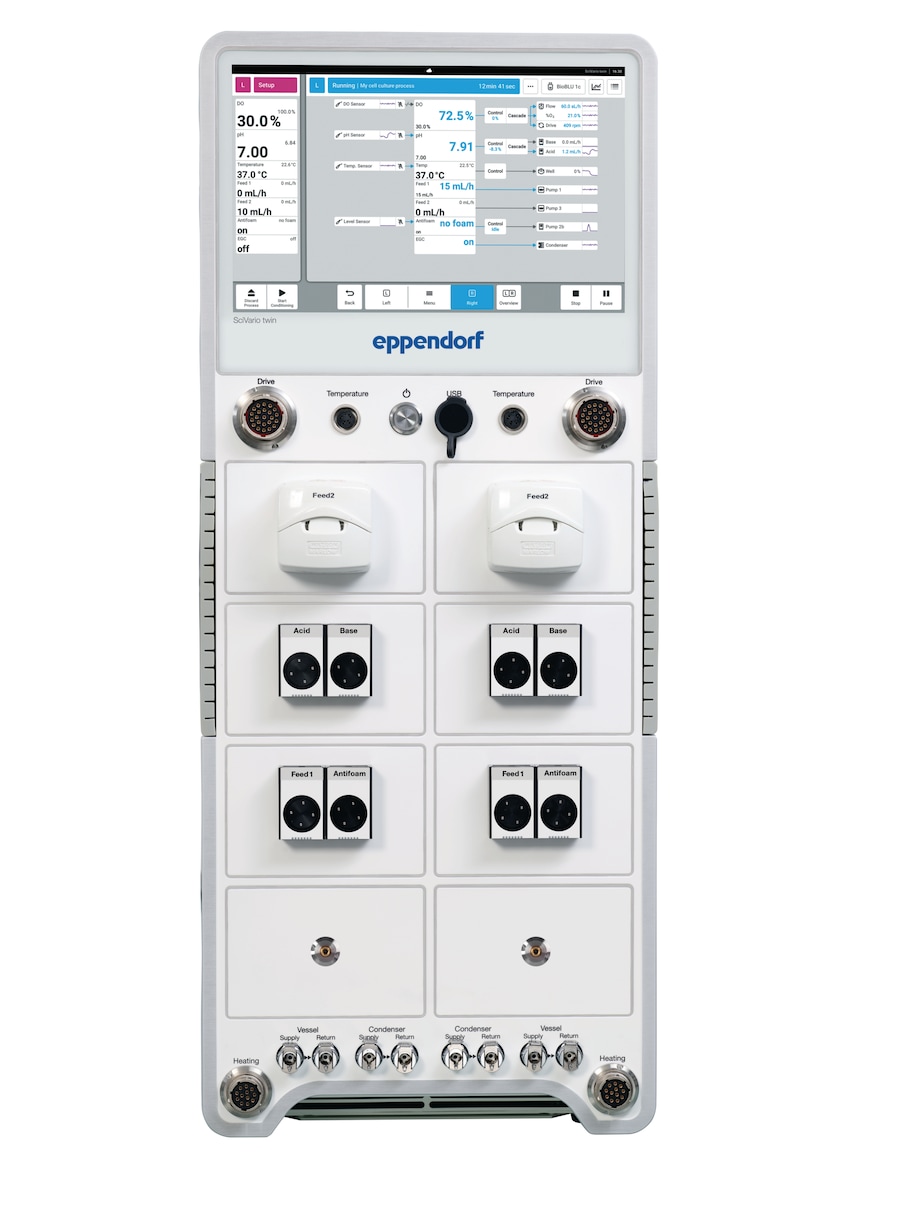

SciVario® twin

• Échantillonnage automatique de jusqu’à 8 bioréacteurs

• Compatible avec les bioréacteurs en verre et à usage unique

• Volume de travail : 200 mL à 10 L

BioFlo® 320

• Échantillonnage automatique de jusqu’à 4 bioréacteurs

• Compatible avec les bioréacteurs en verre et à usage unique

• Volume de travail : 320 mL à 10,5 L

Lire plus

Lire moins

Applications

- Recherche et développement en microbiologie et culture cellulaire

- Convient aux levures et bactéries aérobies et anaérobies, ainsi qu’aux lignées cellulaires de mammifères

- Convient aux systèmes de contrôle des bioprocédés à petite échelle et à l’échelle de laboratoire

- Adapté aux processus discontinus, semi-continus et continus.

Caractéristiques

- Fonctionnement aseptique ne nécessitant pas une hotte à flux

- Compatible avec différentes tailles de verre et BioBLU® Single-Use Bioreactors avec des volumes de travail allant de 60 mL à 10 L

- Convient pour les fioles d’échantillon de 1,5 mL et 10 mL, possibilité de stocker jusqu’à 648 échantillons

- Prélèvements réguliers 24/7

- Stockage des échantillons entre 4 et 40 °C.

- La procédure de nettoyage à l’éthanol est similaire aux procédures utilisées pour le prélèvement manuel d’échantillons

- Le volume mort faible minimise la réduction du volume de culture

- Le design modulaire facilite la multiplication du nombre de bioréacteurs dans lesquels effectuer les prélèvements, ainsi que la conversion de systèmes de bioprocédés existants

- L’ajout de bolus est disponible en option, soit à un moment prédéfini, soit en fonction d’un événement, grâce à la fonction de script du logiciel

- La commande de l’échantillonneur automatique pour bioprocédés est intégrée au logiciel de bioprocédés DASware® control