-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

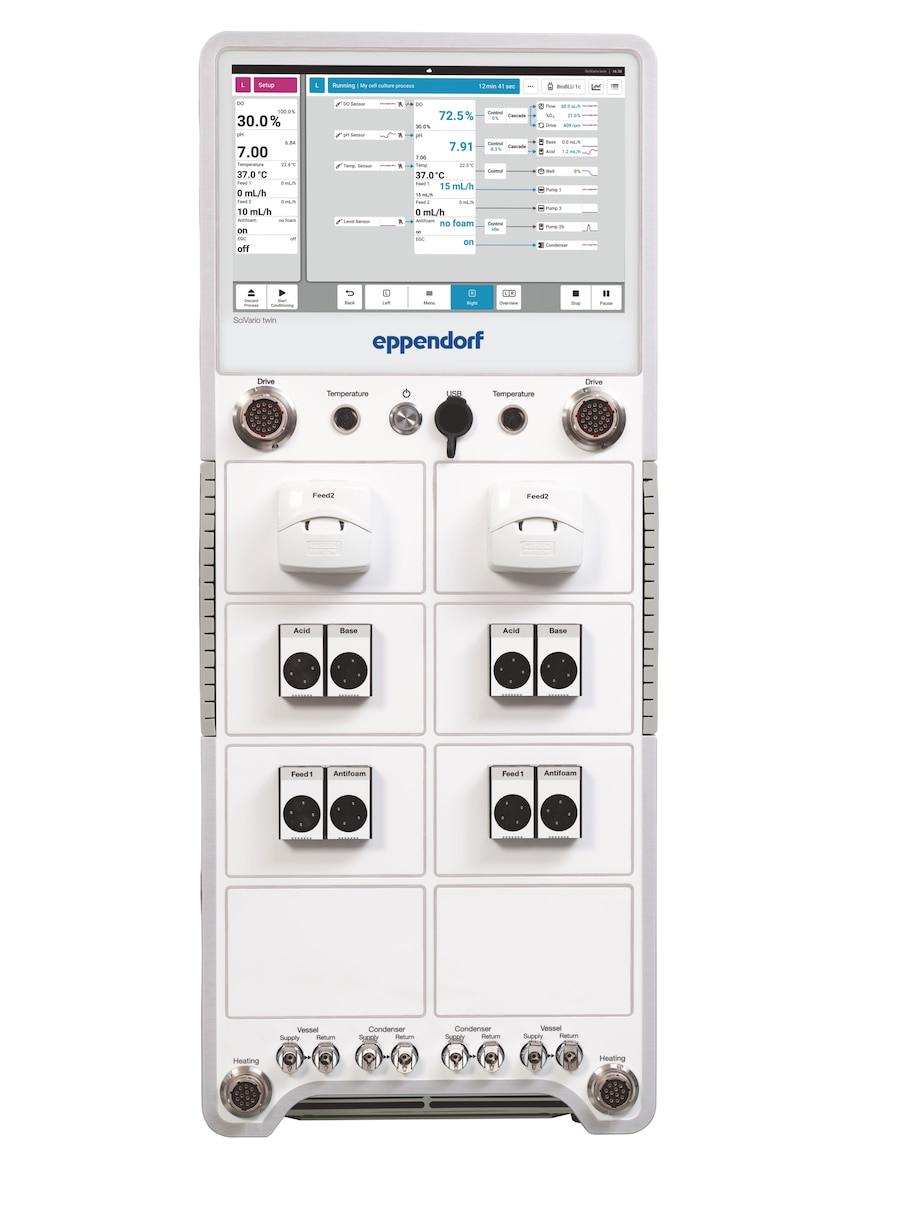

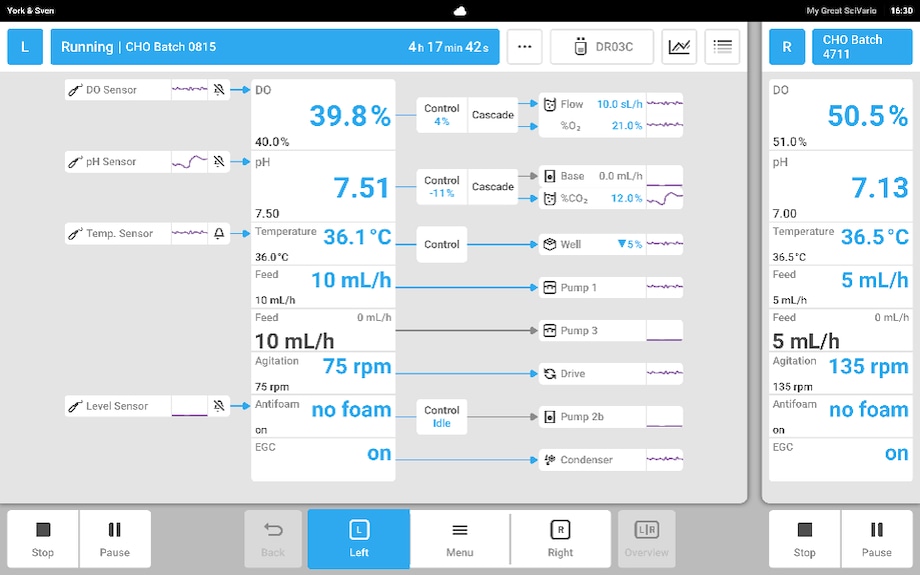

SciVario® twin

SciVario twin cropped, front, grey lines

Volume de travail de 0,2 – 3,8 L (autoclavable),

Volume de travail de 0,25 – 40 L (usage unique)

SciVario twin Angled Bench, Microbiology

Product Information

The SciVario twin is a bench-scale parallel bioprocess controller capable of operating two bioreactors individually. It is suitable for cell culture and fermentation applications in R&D and can be used with glass and BioBLU® Single-Use Bioreactors. The SciVario twin is a modular system, making it customizable as well as easily upgradable after installation and therefore adaptable to changing requirements.

You will find additional download material at the bottom of this page

Products (1)

Services (4)

Accessories (9)

Spare Parts (5)

1 Products

|

|

Show more Products

Product Information

Technical Data

Applications

Features

Product Information

The SciVario twin keeps you flexible, wherever your research focus will take you in the future. The future-proof systems can adapt to changing requirements and like this reduce future capital investment.

• Run both microbial and cell culture processes without any hardware adaptations.

• Choose from a wide variety of glass and BioBLU Single-Use Bioreactors, with working volumes from 1.25 to 3.8 L for all and up to 40 L for single-use cell culture bioreactors.

• Upgrade the system’s hardware easily.

• Expand its capabilities: Integrate the SciVario twin with the DASware® software suite and BioNsight® cloud for advanced process control, and remote process monitoring and data analysis, respectively. Integrate it with the Bioprocess Autosampler for automated sampling 24/7.

Stay flexible with the future proof bay drawer concept

• Eight bays can be equipped with different pumps or other modules.

• The system can be initially delivered with custom configurations and easily upgraded with additional modules to support the changing needs in R&D.

• This concept supports you as a user to avoid additional capital investments into instruments to match future requirements.

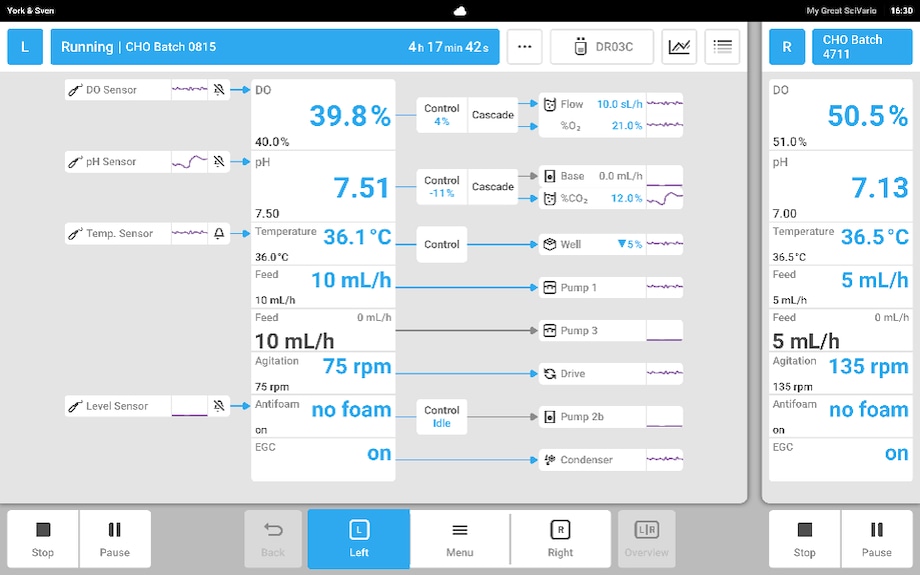

Individually control two bioreactors in parallel

• With the SciVario twin you can run one bioreactor or two bioreactors in parallel.

• The two bioreactors can be controlled individually in any combination of vessel type and working volume.

• Parallel processing allows for more runs in less time.

Optimize your workspace

• The compact design of the SciVario twin frees up bench space.

• The device can be easily moved for cleaning and servicing.

• You can easily access often used connectors/accessories, as they are placed on the front.

• Cable management guides and a storage system for accessories let you keep your bench clean and tidy.

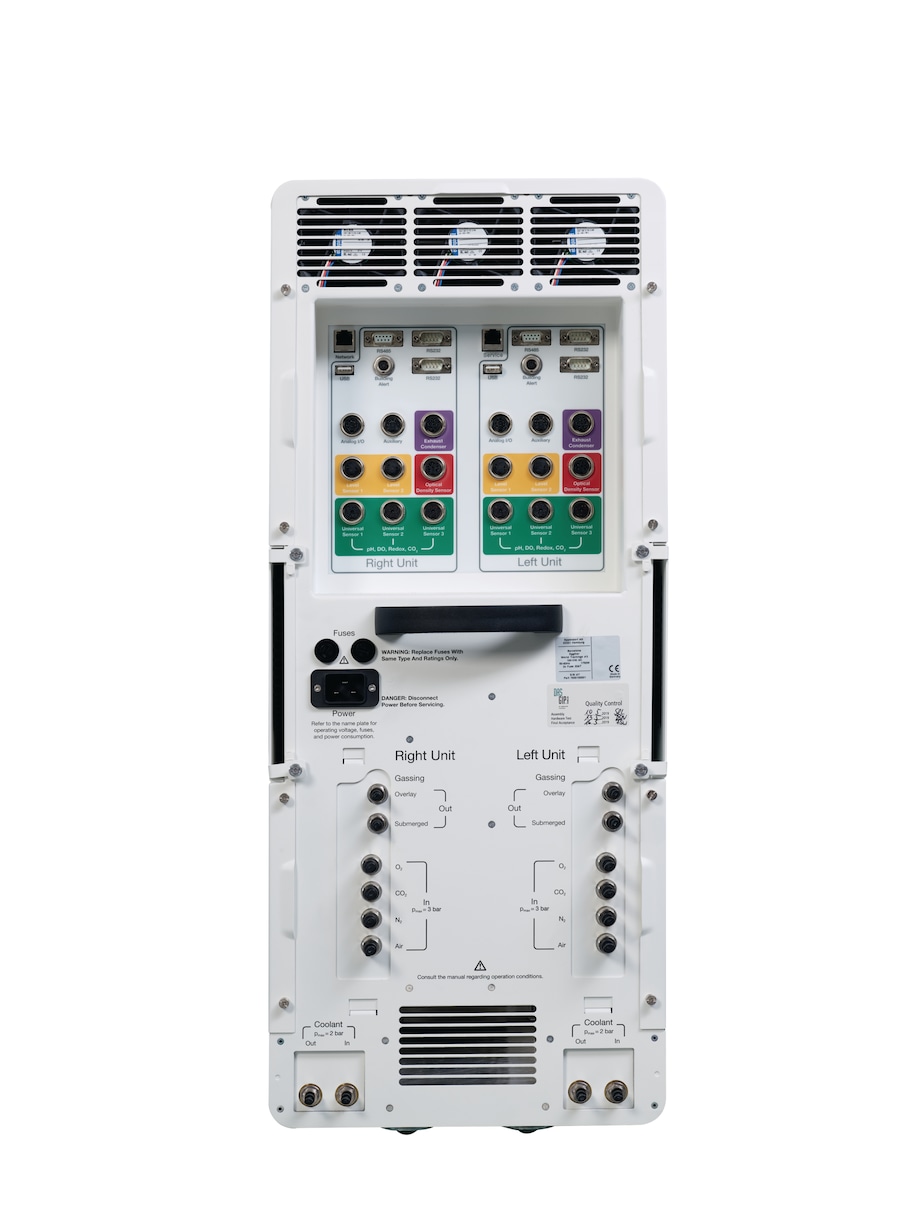

Stay flexible in your process control

• The SciVario twin can be connected with digital and analog sensors and detects them automatically.

• The SciVario twin allows for optical pH measurement.

• Be flexible in your gassing strategy by choosing between submerged and overlay gassing with four gases with individual wide-range TMFCs.

• Flexibly add liquids with up to eight pumps per bioreactor. A wide pump flow rate enables the precise additions of small volumes as well as bigger additions to larger vessels.

• You can flexibly select the required pumps and exchange them after purchase.

• The SciVario twin is compatible with the Bioprocess Autosampler for automated sampling and bolus addition.

Software: Combine ease of use and high performance

• All critical process parameters such as temperature, gassing, pH, feeding, and others can be controlled and recorded by the base unit.

• An intuitive user interface and guided workflows assist you through your process to avoid errors.

• The integration with DASware® control offers advanced functionality, like the execution of feed profiles and scripts, process automation, and the integration of 3rd party sensors.

• The connection to BioNsight® cloud software enables remote monitoring and advanced data analysis.

Read More

Read Less

Technical Data

| Specifications | SciVario twin |

|---|

| Power supply | 100 – 240 V, 50/60 Hz |

| Max. power consumption | 1750 W |

| Dimensions (W × D × H) | 30.6 × 34 × 75 cm / 12.0 × 13.4 × 29.5 in |

| Product weight | 43.1 kg |

| Bacteria/Yeast/Fungi | yes |

| Mammalian/Animal | yes |

| Insect | optional |

| Interchangeable Vessels | yes |

| Validatable | no |

| Stem cells | yes |

|

Bioreactors |

|

| Vessels | Glass/single-use vessels |

| Total volume | 1.3 L to 3.8 L for all variants, up to 40 L for single-use cell culture |

|

Agitation |

|

| Drive | Direct/magnetic overhead drive |

| Speed ranges | 60 – 1,600 rpm/25 – 1,250 rpm/25 – 1,900 rpm |

|

Gassing |

|

| Gas supply | TMFC; overlay and/or sparger |

| Standard gas flow rates | 0.1 – 1,200 sL/h |

| Standard gas mixing | Air, N2, O2 and/or CO2 |

|

Feeding |

|

| Feed lines per vessel | Up to 6 |

| Standard feed rates (depending on tube diameter) | 0.005 – 600 mL/h (small pump), 4.5 – 5,200 mL/h (large pump) |

|

Monitoring and Control |

|

| Exhaust condensation | Liquid-free (Peltier) or water-based |

Applications

- Universal bench-scale controller for research and development in cell culture and microbiology

- Fermentation of bacteria, yeasts, and fungi

- Cultivation of mammalian, insect, and human cell lines

- Cultivation of stem cells

Features

- Customizable and flexible thanks to the innovative bay-drawer concept for further extension and reconfiguration

- Integrated digital sensor technology (Mettler Toledo® ISM® and Hamilton ARC®), supporting analog sensors for pH and DO and optical DO sensors

- Optional PreSens® optical DO sensor technology for BioBLU Single-Use Bioreactors

- Variable speed pumps for accurate liquid addition and operation in batch and fed-batch mode

- Wide range TMFC to allow for individual mixing of air, N2, O2, and CO2 to headspace and/or submerged aeration

- Individual or parallel operation of two glass and/or BioBLU Single-Use Bioreactors, in any combination of bioreactor types

- Compact design, 16-40 cm of benchspace needed per vessel

- Cable management guides for a clean and tidy setup

- Temperature control block for advanced and user-friendly temperature control or temperature control via heat blankets and cooling fingers (benchtop bioreactors)

- Compatible with DASware® control software and BioNsight® cloud software

- Compatible with Bioprocess Autosampler