MENU

BD | BDT

BD | BDT

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

You are about to leave this site.

Please be aware that your current cart is not saved yet and cannot be restored on the new site nor when you come back. If you want to save your cart please login in into your account.

No results found

Search Suggestions

Bioprocess Autosampler

Bioprocess Autosampler dual head system, 4x DASbox, bottles side, front view, cropped

Bioprocess Autosampler:

Modular autosampling solution for small and bench scale bioprocess systems

Modular autosampling solution for small and bench scale bioprocess systems

Bioprocess Autosampler sample storage 1

Efficient sampling from bioreactors of different sizes. Different sample sizes with aseptic operation and low dead volume.

Gain Better Bioprocess Data with Less Effort

Videos not loading, because cookies have been rejected. Change your

Product Information

The Bioprocess Autosampler takes samples from multiple bioreactors and stores them tempered for later analysis. It is compatible with glass and single-use bioreactors operated with a DASbox® Mini Bioreactor System, DASGIP® Parallel Bioreactor System, SciVario® twin or BioFlo® 320 bioreactor control system.You will find additional download material at the bottom of this page

Products (2)

epServices (4)

Accessories (8)

2 Products

Catalog no.

7700200007

|

Catalog no.

7700200008

|

Show more Products

Added to Your Cart

Product Information

Applications

Features

Product Information

Gain Better Bioprocess Data with Less Effort:

You often need to sample your culture during the bioprocess, not just at the end. These samples help you monitor growth, product formation, and nutrient consumption. This way, you can identify interdependencies and take action at predefined times or specific events, like DO rising after carbon source depletion. The Bioprocess Autosampler from Eppendorf provides this solution to you. Whether you are working in cell culture or fermentation, in early R&D or process development, and using single-use or glass bioreactors, this system covers it all. The Bioprocess Autosampler can handle sampling and bolus addition at short, regular intervals, helping you gain complete datasets and automate bioprocess control.

The advantages of automated sampling:

Short and regular sampling intervals help obtaining strong datasets. Regular measurement of process parameters, the cells' status, and the concentration and quality of the product is the basis for a comprehensive view on the process. Such information is indispensable for process optimization.

You often need to sample your culture during the bioprocess, not just at the end. These samples help you monitor growth, product formation, and nutrient consumption. This way, you can identify interdependencies and take action at predefined times or specific events, like DO rising after carbon source depletion. The Bioprocess Autosampler from Eppendorf provides this solution to you. Whether you are working in cell culture or fermentation, in early R&D or process development, and using single-use or glass bioreactors, this system covers it all. The Bioprocess Autosampler can handle sampling and bolus addition at short, regular intervals, helping you gain complete datasets and automate bioprocess control.

The advantages of automated sampling:

Short and regular sampling intervals help obtaining strong datasets. Regular measurement of process parameters, the cells' status, and the concentration and quality of the product is the basis for a comprehensive view on the process. Such information is indispensable for process optimization.

Automated sampling

• Facilitates sampling 24/7 in regular, short intervals

• Time is freed up for other tasks

• Automated sample storage reduces risk for human error

Sampling Procedure

• The Bioprocess Autosampler holds one sampling port per bioreactor

• Tubing connects the sampling port with a dip tube in the bioreactor

• Sampling ports harbor a septum, which preserves the sterility of the bioreactor

• For sampling, a needle connected to a syringe is automatically inserted into the port, pinching through the septum

• The sample is transferred to a sampling vial by pinching through a septum in the vial lid

Compatible Small Scale Bioprocess Control Systems

The Bioprocess Autosampler can be installed with new as well as retrofitted to existing small scale bioreactor control systems.

DASbox® Mini Bioreactor System

• Autosampling of up to 16 bioreactors

• Compatible with glass and single-use bioreactors

• Working volume: 60 – 250 mL

DASGIP® Parallel Bioreactor System

• Autosampling of up to 16 bioreactors

• Compatible with glass and single-use bioreactors

• Working volume: 200 mL – 1.8 L

Compatible Bench Scale Bioprocess Control Systems

The Bioprocess Autosampler can be installed with new as well as retrofitted to existing bench scale bioreactor control systems.

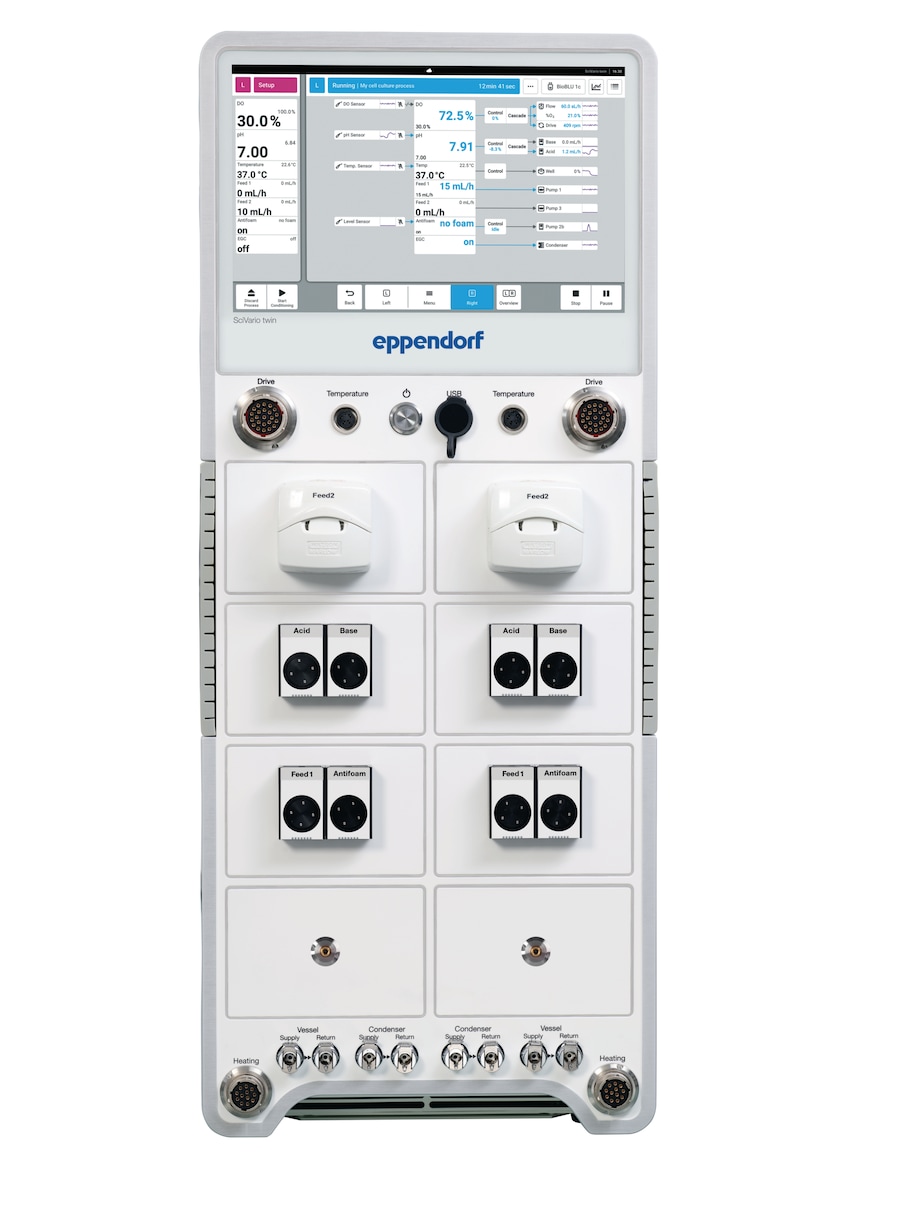

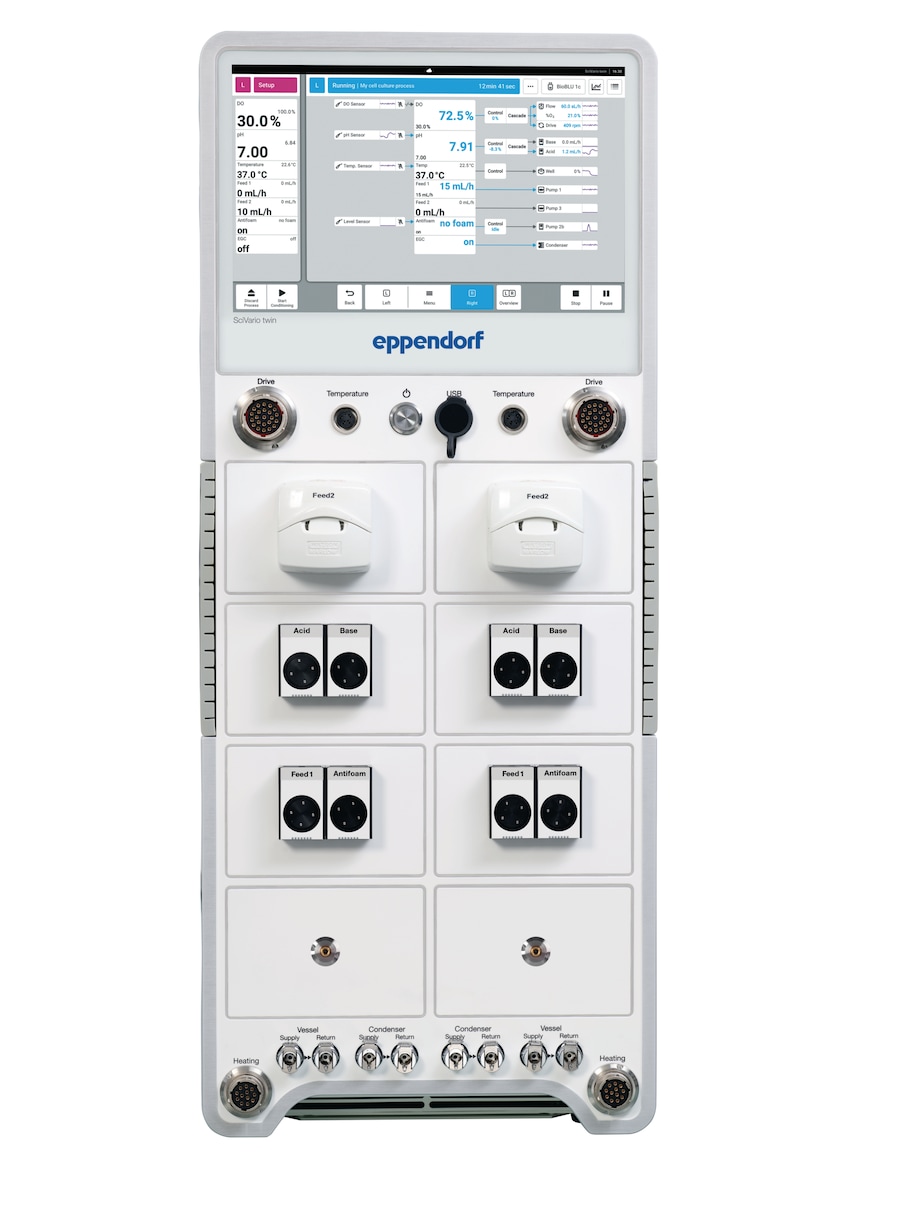

SciVario® twin

• Autosampling of up to 8 bioreactors

• Compatible with glass and single-use bioreactors

• Working volume: 200 mL - 10 L

BioFlo® 320

• Autosampling of up to 4 bioreactors

• Compatible with glass and single-use bioreactors

• Working volume: 320 mL – 10.5 L

Read More

Read Less

Applications

- Research and development in microbiology and cell culture

- Suitable for aerobic and anaerobic bacteria and yeasts, as well as mammalian cell lines

- Suitable for small scale and bench scale bioprocess control systems

- Suitable for batch, fed-batch, and continuous processes

Features

- Aseptic operation without the use of a laminar flow cabinet

- Compatible with differently-sized glass and BioBLU® Single-Use Bioreactors with working volumes of 60 mL to 10 L

- Suitable for 1.5 mL and 10 mL sample vials, up to 648 samples can be stored

- Enables regular sampling 24/7

- Sample storage between 4 and 40 °C.

- Sanitation procedure using ethanol is similar to procedures, usually applied when sampling manually

- Low dead volume minimizes the reduction of culture volume

- Modular design that facilitates expansion of the number of bioreactors to be sampled and retrofitting of existing bioprocess systems

- Bolus addition is available as an option, either at a pre-defined time or event-based through the scripting feature in the software

- Control of the Bioprocess Autosampler is integrated in DASware® control bioprocess software