Innova® U535 - ULT Freezer

Product Information

You need a compact ULT freezer for the lab?The Eppendorf Innova U535 ULT (ultra-low temperature) freezer minimizes operating costs while providing superior protection for your critical samples at -80°C. A combined insulation based on vacuum insulation panels and polyurethane foam enables extremely low energy consumption for longterm sample storage.

You will find additional download material at the bottom of this page

Services (13)

Accessories (4)

VisioNize (3)

|

|

|

|

|

|

|

|

|

|

Catalog no.

0082070009

|

|

|

|

|

|

|

|

Catalog no.

0082070280

|

Product Information

Applications

Features

Product Information

PhysioCare

Besides sustainability, the main focus of our freezers is on ergonomic aspects. Easy closing of the outer door, ergonomic door handle, display on eye-level, or easy-to-clean stainless steel interior are based on the Eppendorf PhysioCare Concept: Safe grip but very light forces needed to open and close the freezer door.

Cost of ownership

When investing in a new ULT freezer, the product price itself is only one aspect. Others include the long-term costs of power consumption and the costs of service and spare parts. Keep in mind, a high-quality ULT freezer will do its job in the lab for 10 years or more.

Sample safety

The Innova line is equipped with reliable heavy-duty compressors (2-stage cascade cooling system). Quick pull-down times enable fast re-use after cleaning/defrosting of the instrument. The freezers have short recovery times after opening as well as built-in voltage stabilizers to provide extra sample safety.

The freezer temperature range is from -50 °C to -86 °C.

For even higher sample safety, the Eppendorf Innova upright freezers can be equipped with CO2/LN2 back-up systems and a chart recorder. Temperature monitor systems can be used to monitor the freezers remotely.

Sustainability

Sustainability for ULT freezers is a challenge: Maintaining extremely low temperatures of -86 °C for 24 hours a day, 7 days a week needs energy.

By following the epGreen concept, the Eppendorf freezer R&D team developed intelligent solutions where energy savings are combined with durable long-lasting product quality and ergonomic aspects. This future-oriented instrument class provides consumption levels which are ahead of most competitors within this volume class.

Support the epGreen initiative with your Eppendorf ULT freezer

Eppendorf Ultra-Low Temperature freezers are among the most energy-efficient in the industry, reducing energy consumption by thousands of kilowatt hours over our competition.

Factors influencing the energy consumption

• Thickness of insulation

• Type of insulation

• Type of cooling liquid

• Efficiency of compressors

• Control of compressor

• Pressure in cooling system

• Style of cooling loops (diameter, length, density,..)

• Sealings of outer door

• Sealings of inner doors

• Insulation of inner doors

• Insulation of outer door

Our part for sustainability

• Production moved into new building with state-of-the-art building insulation to save heating energy and power

• Heat output during final individual unit testing discharges building heating system

• Plastic and cardboard compactors introduced + waste rebate system in place

• Local requirements for waste management (collection of electronic waste like circuit boards, recycling via authorized recycling organizations) and internal guide lines

• Usage of green cooling liquids in Eppendorf ULT freezers for 10 years

• Packaging parts have increasing share of recycled origin

• Packaging is more than 99% recyclable (wood, cardboard, PE-foil)

• REACH + RoHS compliant

• ENERGY STAR® partner

• Marketing material is printed on certified paper, wherever possible focus on pdf only

• Shipment by cargo ship to reduce CO2 footprint

Learn more about sustainability at Eppendorf

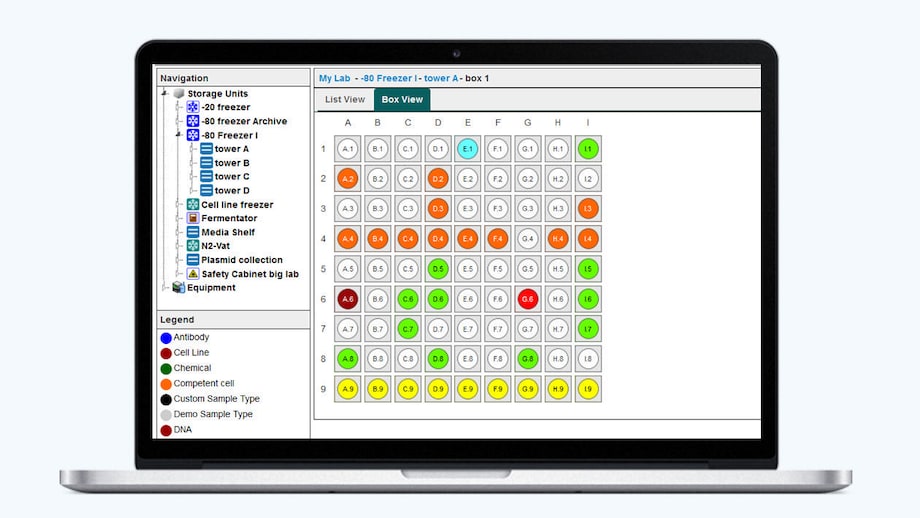

Lost in samples? Stay organized!

Over many years, you collect hundreds and thousands of samples – samples that are the results of years of hard work – samples of high value. When storing these in the ULT freezer at -80°C, it is vital to keep them safe and accessible.

Many scientists still use spreadsheets or even paper-based lists to keep track of their storage. While these solutions may work most of the time, they are susceptible to human error, damage, and misplacement.

Keep track of your samples with eLabInventory

eLabInventory is a sample management software.

Start a free 30-day trial!

Visit www.eLabInventory.com

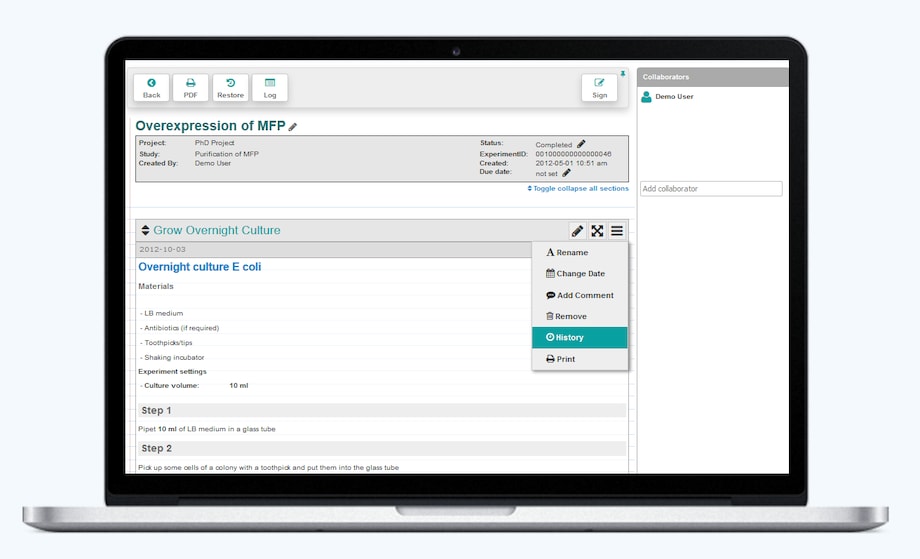

Struggling with paper-based documentation?

The eLabJournal Electronic Lab Notebook offers an intuitive and flexible solution to document research and track research data like workflow processes where the ULT freezer is involved. Improve efficiency when documenting, organizing, searching, and archiving collected data. With the free eLabJournal add-ons, you can extend the functionality of eLabJournal to a fully integrated Laboratory Information Management System.

Start a free 30-day trial!

Visit www.eLabJournal.com

Efficient lab and device management with VisioNize

® Lab Suite

Are you interested in monitoring your lab devices and receiving notifications e.g., for device alarms? A digital, connected lab offers even more.

Gain access to a modular range of digital services and choose what works for your lab. VisioNize Lab Suite offers everything you need as a Lab Manager or Scientist to get started to digitally manage your lab for increased sample security, compliance needs and maintenance management.

Chart your own course to digital lab excellence! Find out more

End-of-Life

Disposal of packaging

The packaging of the ULT freezer contains different materials, this includes a wooden pallet, cardboard, a plastic dust cover, and some foam parts. Recycling of materials becomes more and more important every day: Are you aware that nearly all cardboard material is recycled in Europe? Our freezer packaging cardboard material consists of ca. 70% recycling material. Please support the global sustainability initiative of recycling valuable raw material by also collecting the freezer cardboard packaging material and disposing of it in the appropriate collection container at your organization. In respect to the plastic dust cover made of LD-PE and the foam parts, we recommend to select a dedicated recycling partner where PE material can be recycled. We suggest you contact your local waste hauler or facility management team to understand the available recycling options for your organization.

Disposal of instrument

Our freezers last for many years, but if they need to be replaced, we kindly ask you to fulfill local requirements for disposal of these instruments. We strongly recommend a certified local recycling partner with experience in instruments with active cooling. Keeping it “local“ reduces the impact of transportation, and the „certified“ aspect is recommended due to the safe and sustainable removal and recycling of the cooling liquids.

Decontamination

This piece of equipment was used in a laboratory and/ or was used to handle biological samples. Please keep in mind to adequately decontaminate the equipment which needs to be disposed. Check local requirements. For more information, get in contact with your local biosafety officer and/ or waste officer. Check if your local recycling partner has special instructions and/ or documentation requirements. You may also use the Eppendorf decontamination form sheet as guidance.

Downloads: Innova® U535

Filter

Reset all