MENÜ

AT | EUR

AT | EUR

-

- Tischzentrifugen

- Standzentrifugen

- Gekühlte Zentrifugen

- Mikrozentrifugen

- Mehrzweckzentrifugen

- Hochgeschwindigkeitszentrifugen

- Ultrazentrifugen

- Concentrator

- IVD Produkte

- High-Speed and Ultracentrifuge Consumables

- Zentrifugenröhrchen

- Zentrifugenplatten

- Gerätemanagement

- Proben- und Informationsmanagement

Es konnten keine Ergebnisse gefunden werden.

Such-Empfehlungen

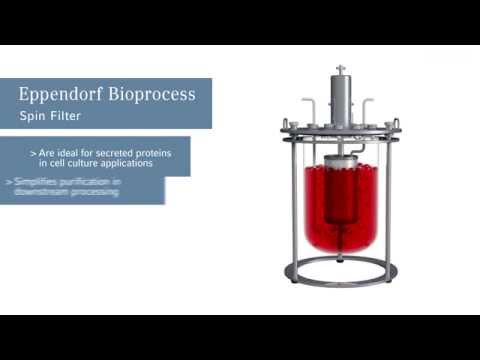

BioFlo® Pro

Cell Culture Impellers

Das Video kann nicht geladen werden, da Cookies abgelehnt wurden. Ändern Sie Ihre

Produktinformationen

Large-scale industrial system with full adherence to GMP and GAMP® guidelinesDokumente zum Download finden Sie weiter unten auf der Seite

Services (12)

12 Services

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mehr Produkte anzeigen

Zum Warenkorb hinzugefügt

Produktinformationen

Applikation

Eigenschaften

Produktinformationen

BioFlo Pro fermentors are modular systems designed for quick delivery, dependable operation, and system flexibility, all at an affordable price. BioFlo Pro systems utilize industry-standard components for dependable operation, and an Allen Bradley® CompactLogix™ programmable-logic controller (PLC) for easy integration into any production facility. The modular design enables multiple options to be added, removed, or changed at any time to meet your various process requirements. Vessels available in 120, 240, 400, 1,200, and 2,400 liter sizes.

Air inlet line

• Thermal Mass Flow Controller

• Dual inlet air filters (in series)

• Dual-inlet air flters with test integrity ports

• Gas overlay

• 2-gas mix (O2 supplementation)

Impellers

• Rushton-type

• Pitched-blade

• Marine

Addition and sampling

• Sampling valve (Resterilizable)

• Sterile sampling assembly

• Resterilizable addition valves

Additional otions

• Clean-in-place option (transfer panel/spray balls)

• Glycol/chiller heat exchanger

• Low pressure seal alarm for double-mechanical seal

• Vessel electropolish

• System passivation

• Transfer lines (resterilizable)

• Addition vessel scales

• DeltaV™ connectivity

Air inlet line

• Thermal Mass Flow Controller

• Dual inlet air filters (in series)

• Dual-inlet air flters with test integrity ports

• Gas overlay

• 2-gas mix (O2 supplementation)

Impellers

• Rushton-type

• Pitched-blade

• Marine

Addition and sampling

• Sampling valve (Resterilizable)

• Sterile sampling assembly

• Resterilizable addition valves

Additional otions

• Clean-in-place option (transfer panel/spray balls)

• Glycol/chiller heat exchanger

• Low pressure seal alarm for double-mechanical seal

• Vessel electropolish

• System passivation

• Transfer lines (resterilizable)

• Addition vessel scales

• DeltaV™ connectivity

Applikation

- Pilot- and large-scale fermentation of aerobic and anaerobic bacteria, yeasts, fungi, and insect cells

- Suitable for batch, fed-batch, and continuous processes

Eigenschaften

- Large scale pilot/production system

- Modular design with over a hundred options allows for high level of customization pre and post delivery

- Multiple impeller and gas flow options

- NEMA-4 (IP65) rated control cabinet with industry-standard Allen Bradley® PLC

- Open piping skid allows for easy accessibility

- Fully automated SIP sequence for sterilization

- Clean-in-Place (CIP) options available for vessel and piping

- Flush mounted vessel ports for enhanced vessel design and drainability

- Documentation packages available for system qualification in GMP regulated processes

- ASME-rated pressure vessel