MENU

AR | ARS

AR | ARS

You are about to leave this site.

Please be aware that your current cart is not saved yet and cannot be restored on the new site nor when you come back. If you want to save your cart please login in into your account.

No results found

Search Suggestions

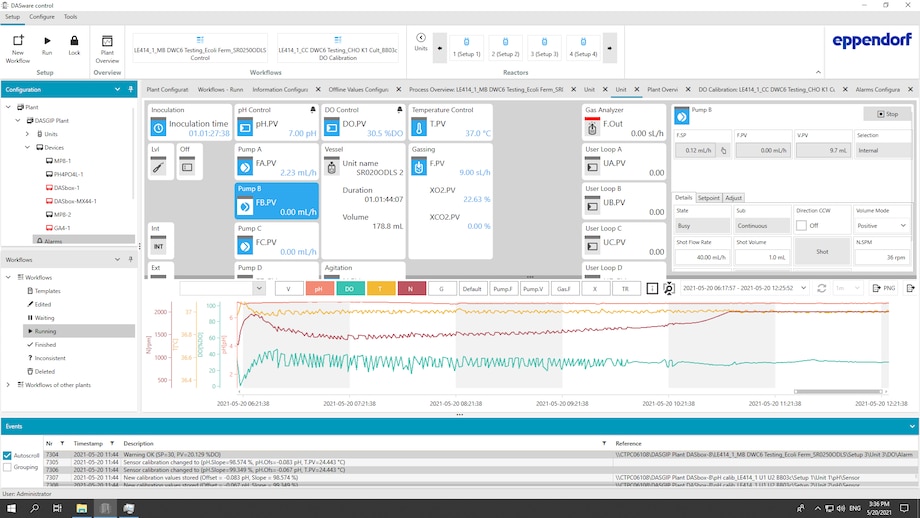

DASware® control

DASware control single

DASware control

• Monitorización, control y registro de datos del proceso avanzados para el cultivo en paralelo con control individual de cada biorreactor

• Monitorización, control y registro de datos del proceso avanzados para el cultivo en paralelo con control individual de cada biorreactor

DASGIP Parallel Bioreactor System, BioBLU 1c woman and man

El diseño paralelo del DASware control permite el manejo del DASGIP Parallel Bioreactor System con hasta 16 recipientes.

DASware control 5 lab, woman at PC

Con DASware control 5, los sistemas de biorreactores paralelos DASGIP se pueden operar con hasta 16 recipientes.

Product Information

Operating multiple bioreactors in parallel significantly reduces the number of runs needed and thus accelerates process development. With DASware control, Eppendorf offers a bioprocess control software that enables the user to run 16 and more individually controlled bioreactors in parallel, including parallel calibration procedures for a quick set–up.You will find additional download material at the bottom of this page

Products (4)

Accessories (1)

4 Products

|

|

|

|

|

|

Catalog no.

78600189

|

Show more Products

Added to Your Cart

Product Information

Features

Product Information

DASware control is the bioprocess control software at the core of all DASGIP Parallel Bioreactor Systems and the DASbox Mini Bioreactor System and offers a parallel process design right from the scratch. Combined with extensive embedded process automation features, intelligent recipe management and integrated report generating capabilities it delivers an unprecedented level of integral process documentation.

The seamless integration of industry-leading OPC communication enables implementation of a host of solutions associated with QbD, DoE, PAT and the like. These are offered in the powerful DASware solution suite that integrates with DASware control.

The seamless integration of industry-leading OPC communication enables implementation of a host of solutions associated with QbD, DoE, PAT and the like. These are offered in the powerful DASware solution suite that integrates with DASware control.

Features

- Parallel process control with individual control of each vessel: DASbox Mini Bioreactor System: up to 24 vessels, DASGIP Parallel Bioreactor Systems: up to 16

- Seamless integration with SciVario twin and BioFlo systems (up to 8 controllers)

- Integrated batch functionality for process and recipe management

- Ideally suited for Design of Experiments (DoE)

- Parallel calibration and cleaning procedures

- Customized views and user-defined functions

- Automated data export, reporting and chart creation for Microsoft® Excel®

- Professional database with managed access (Postgre SQL Server)

- OPC communication for easy integration with third party-equipment using DASware connect and DASware analyze

- Integrated analysis of offline values, online calculated values, and alarm notification

- IQ/OQ package available